Best Acrylic Light Guide Plate

Acrylic LGP, Thickness from 2mm to 15mm, Cut to size, OEM/ODM Service…

Top Supplier of Acrylic Light Guide Plates

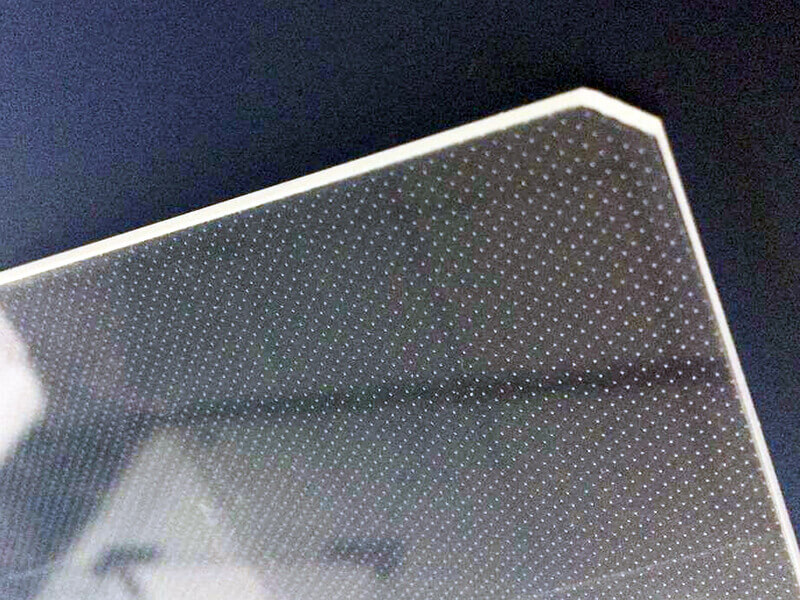

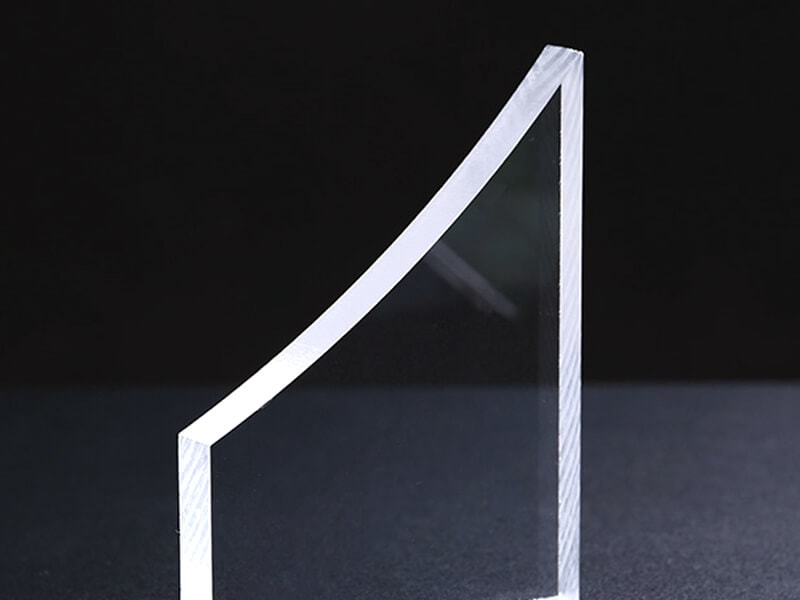

Light Guide Plate is used to transform a line light source into a surface source for LED panel light, advertising display, kiosk, bulletin board, traffic signboards, etc. It is made of specific acrylic sheets with excellent optical performance, great weather resistance, extremely transparent. Some people like to call it “LGP”.

With high-quality optical grade acrylic substrate, the light guide panel (LGP) can direct LED light to matrix lines or regular dots, which is made by a laser engraving machine. The light guide panel (LGP) is made under a constant temperature, constant humidity, and dust-free environment. Therefore, it has the characteristics of ultra-thin and super bright, uniform light guiding, energy-saving, and environment-friendly, no dark area, durable, not easy to yellow, simple and quick installation and maintenance.

UVACRYLIC is a leading supplier of acrylic light guide panels in China. Meantime, we use the laser to make matrix lines or regular dots for LED panel lights, advertising display signs, etc. Otherwise, we can provide OEM/ODM services for global clients.

Acrylic Light Guide Plate Details

Dimensions of Acrylic Light Guide Plate

| Item | Model | Thickness Range (mm) | Size (mm) |

|---|---|---|---|

| Acrylic Light Plate | UVAC-LGP | 2mm, 3mm, 4mm, 6mm, custom thickness | 1220×2440, 2000×3000, custom size |

Physical Properties

| Properties | Unit | Value |

|---|---|---|

| Density (clear acrylic) | g/cm^3 | 1.19 |

| Matrix lines or regular dots | Custom | |

| Light transmittance | % | >90 |

| Tensile Strength | Mpa | >70 |

| Charpy impact strength (unnotched) | KJ/m^2 | >13 |

| Tension Modulus of Elasticity | Mpa | >3000 |

| Tensile Strain at break | % | >4 |

| Flexural strength | Mpa | 100 to 115 |

| Charpy impact strength (unnotched) | kj/m^2 | >17 |

| Vicat softening temperature | °C | >105 |

| Dimensional change on heating (shrinkage) | % | <2.5 |

| Total luminous transmittace | % | >90 |

| Rockwell hardness | 100 to 115 | |

| Linear expansion coefficient | K^ -1 | 7×10^-5 |

| Temperature of deflection under load | °C | 95 to 100 |

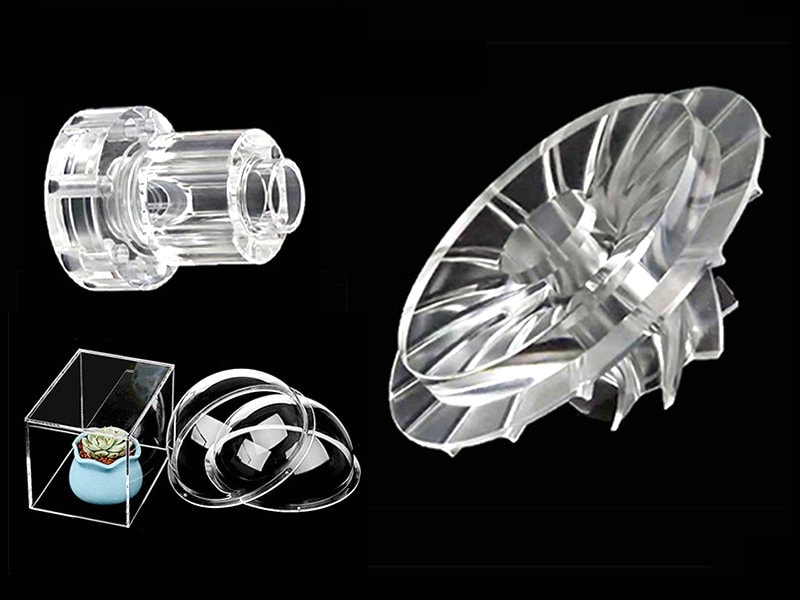

Machining Custom Acrylic Service

With more than 15 years of experience in machining acrylic, UVACRYLIC provides integrated machining solutions for custom acrylic. Today, we have grown to be the top OEM factory of acrylic-based products.

The common machining acrylic methods include cutting, polishing, bending, gluing, coating, CNC Machining, Printing, Drape forming, Injection Molding, Blow Molding, etc.

From common machining, methods, our engineers always find the right solution for all acrylic-based products.

Applications

100% Environment-Friendly Material

100% Raw Material Is Purchased From Lucite And MITSUBISHI Company

REACH Testing Report

RoHS Testing Report

Related Products

Related Blogs

Frequently Asked Questions

Need A Trustworthy Supplier Of Acrylic Light Guide Plate

Click on the button, you will find the Trustworthy Supplier Of Acrylic Light Guide Plates.