Best Acrylic Diffuser Sheets

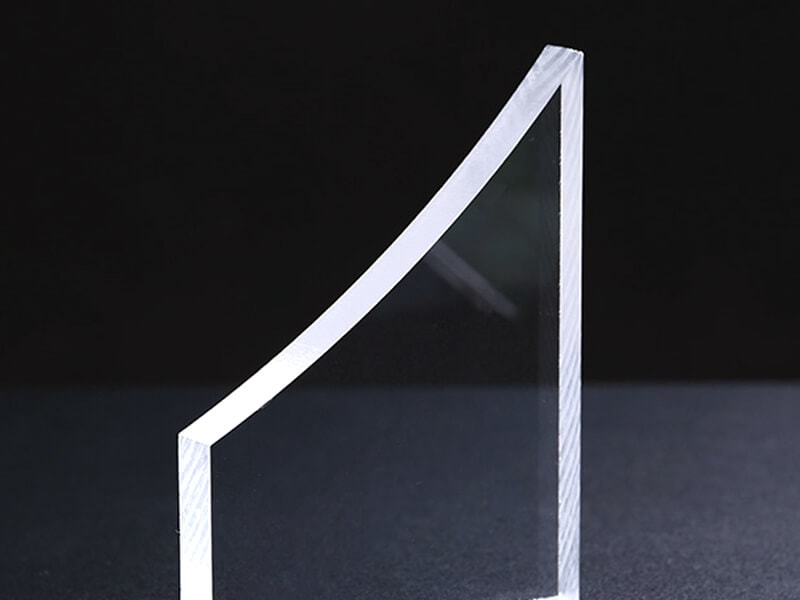

Thickness from 1mm to 8mm, Cut to size…

Top Supplier of Acrylic Diffuser Sheet

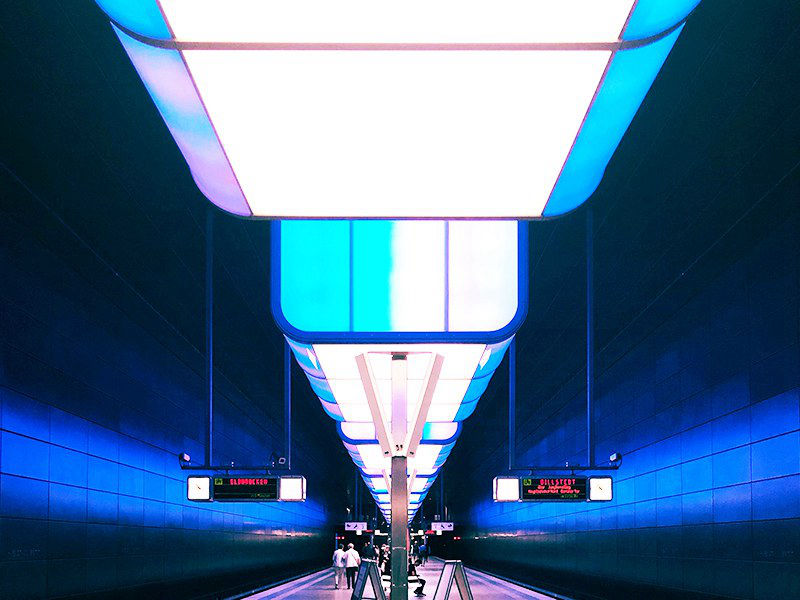

Acrylic Diffuser Sheet is designed and manufactured specifically with superior optical properties, it offers excellent lighting diffusion, even light distribution without dizzy light nor LED light hotspots appearing. Some people call it “acrylic lighting diffuser” or “acrylic diffuser“.

The normal color is white/opal, but it is also suitable for use with different colored LED lighting systems. Acrylic diffuser offers better design flexibility and outstanding formability. Therefore, Acrylic Diffuser Sheet is the right material for LED lighting fixtures for commercial use, POP displays, and backlit signs.

UVACRYLIC is a leading manufacturer of acrylic diffusers in China. We always use virgin raw material, purchased from Lucite and Mitsubishi company. With strict quality control, the annual production capacity is more than 20 thousand tons. Today, we are providing excellent clear acrylic sheets to more than 1200 clients from 40 countries.

Acrylic Diffuser Specification

Standard Dimensions

| Product Name | Model | Thickness | Standard Size | Light transmittance |

|---|---|---|---|---|

| Acrylic Diffuser Sheet | UVAC-DI | 1.5 mm, 2 mm, 2.5mm, 3mm | 1220×2440mm | 75%, 85%, 90% |

| White Acrylic Diffuser | UVAC-DI | 4mm, 5mm, 6mm, 7mm, 8mm, 9mm, 10mm, 12mm | 1220×2440mm | From 40% to 60% |

| Anti-glare Acrylic Diffuser | UVAC-AGDI | 1.2mm, 1.5mm, 2 mm, 2.5mm, 3mm | 1220×2440mm | 93% |

What You Need To Know

Physical Properties

| Properties | Unit | Value |

|---|---|---|

| Density (clear acrylic) | g/cm^3 | 1.19 |

| Tensile Strength | Mpa | >70 |

| Charpy impact strength (unnotched) | KJ/m^2 | >13 |

| Tension Modulus of Elasticity | Mpa | >3000 |

| Tensile Strain at break | % | >4 |

| Flexural strength | Mpa | 100 to 115 |

| Charpy impact strength (unnotched) | kj/m^2 | >17 |

| Vicat softening temperature | °C | >105 |

| Dimensional change on heating (shrinkage) | % | <2.5 |

| Total luminous transmittance | % | >90 |

| Rockwell hardness | 100 to 115 | |

| Linear expansion coefficient | K^ -1 | 7×10^-5 |

| Temperature of deflection under load | °C | 95 to 100 |

| Light transmittance | % | >90 |

Main Benefits

100% Environment-Friendly PMMA Material

Purchased From Lucite And MITSUBISHI Company Directly