Acrylic Vs PETG

Acrylic and PETG both are widely common plastic materials that are used throughout the world. If you’re switching to plastic from glass or metal materials, it might be not very clear for you to choose the right item.

As there are many options in plastic, sometimes it’s harder to pick the right one for your project. If you are following UVACRYLIC, you have known more information about acrylic material. Therefore, we don’t introduce it again. Today in this guide, you’ll know the true comparison of the two most commonly used plastics in any industry, Acrylic, and PETG.

What is PETG?

PETG (Polyethylene terephthalate glycol) is a thermoplastic polyester that provides outstanding toughness with chemical resistance. One of the great features of this material is that it is easy to thermoform.

PETG is a high-impact resistant material, but it does not yield a very good result in outdoor applications. In other words, you can say that it is not suitable for outdoor uses.

If you want to know more about the forming and cutting of this material, you are in the right place. Because, today, we’re going to do a head-to-head comparison of PETG plastic vs Acrylic plastic. And at the end, you’ll know which one is the best for your project.

Acrylic vs PETG: Head to Head Comparison

Applications

Acrylic and PETG are used for various applications such as machine guards, covers, displays, and applications that need to be transparent. One of the great features of both materials is their transparency and clarity.

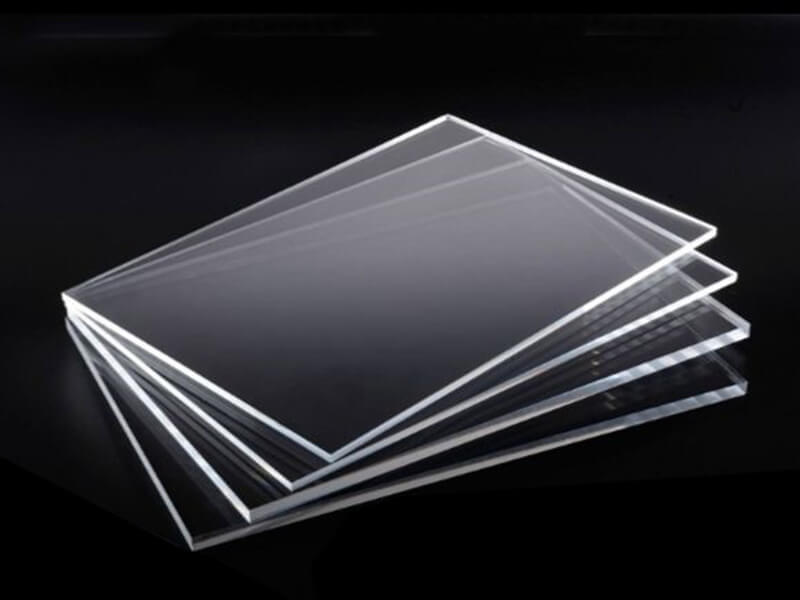

Acrylic: It is available in both extruded and cast. Extruded form of acrylic is the most common and cost-effective use. Cast acrylic is considerably more expensive because of the delicate manufacturing process.

Taking advantage of the natural transparency for extruded acrylic, it is used for displays, lenses, acrylic nails, security barriers, medical devices, LCD lenses. Because of this material’s excellent clarity and durability, this can be used as windows, tanks, and enclosures around exhibits.

Normally, acrylic material can be made into plexiglass sheets, acrylic rods, and acrylic tubes.

PETG: It’s a great choice for machine guarding, especially for medical devices. PETG materials have good chemical resistance making them suitable for cooking oil containers, drinking bottles, and FDA-compliant food. PETG plastics are widely used as packaging materials.

The rigid structure of PETG makes sure that it can undergo hard or sterile processes. For this reason, they can be used for packaging medical and pharmaceutical instruments. And because of its durability, it can often be used as a machine guard as well.

Strength

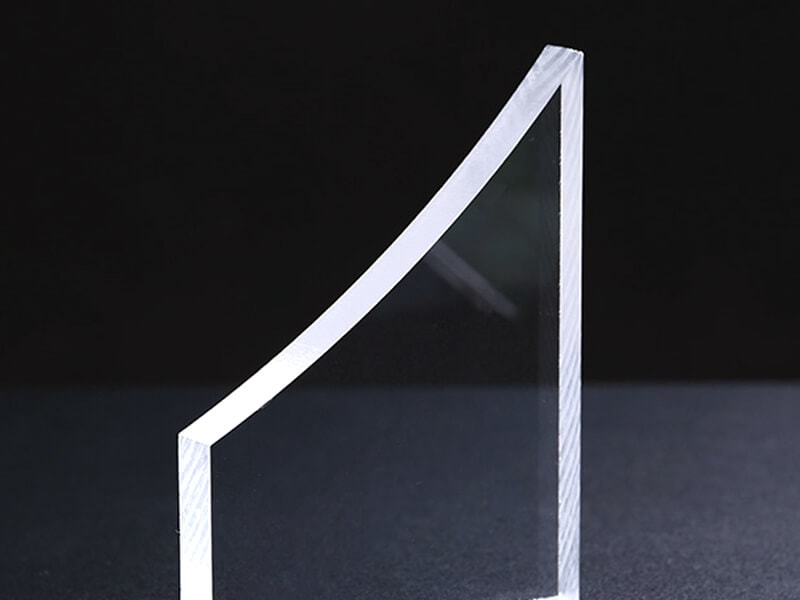

Before talking about the strength, you need to know that PETG plastics are extremely rigid and tough. On the other hand, acrylic plastics are flexible and you can use them for curved applications smoothly.

PETG is 5 to 7 times stronger than acrylic, but this cannot serve outdoor purposes. On the other hand, acrylic plastics are flexible and can be used for indoor and outdoor purposes. Otherwise, polycarbonate sheets are 25 times stronger than acrylic.

It can withstand extreme weather and even resist if you live in an area that has hailstorms. It does not get any scratches, so you don’t need to worry about it if you’re using them for rough applications.

Color

Acrylic plastics are available in standard colors or can be colored as per requirement. PETG plastics can be colored based on costs and production runs.

Cost

PETG plastics are a little bit more pricy and their costs depend on the application of the material. Being more efficient and flexible, acrylic is more affordable compared to PETG plastics. The price of acrylic plastic depends on the thickness of the material.

Production Issues

There are no production issues while producing acrylic plastics. Acrylic is easier to bond compared to PETG plastics. PETG plastics cannot be polished. This might yellow around the edges if an improper laser is used. Also, the bonding of this plastic requires special agents.

Scratches

Acrylic plastics are more scratch-resistant than PETG, and they do not catch a scratch very easily. On the other hand, PETG has a higher risk of catching scratches.

Stability

Compared to PETG, acrylic is easier to break, but this is a flexible plastic. In comparison, PETG is more impact-resistant and rigid. This does not break easily compared to acrylic plastics.

Cleaning

We recommend no harsh cleaning for both acrylic and PETG plastics. Alcohol-based cleaners are not advised. Cracking will become more evident if you apply it to any of these materials. Clean them with soap and water gently by rubbing with the soap and washing with water afterward.

Surface

Acrylic is more scratch-resistant with shiny edges and also clearer than PETG plastics. However, in the case of acrylic, you need to be careful about cracking. PETG plastic is strong but prone to scratches and not as shiny as acrylic.

Durability

Acrylic is flexible, but it can be broken if enough pressure is applied. On the other hand, PETG plastics cannot be broken easily, but there are some issues on where you will set them.

However, if you’re using acrylic plastic for windows, skylights, POP displays, you don’t need to be worried about it. This plastic can withstand harsh weather and very strong impacts as well. Especially compared to glass, the durability and strength are way more superior. The only thing is that it’s not the strongest plastic on the market, but if you’re using it for a not so extreme purpose, it can serve you pretty well.

Workability

It is easy to work with both materials as they are easy to cut with any tools like- jigsaws, circular saw or CNC cutting. However, you should make sure that the blades are sharp enough for cutting as blunt blades will generate heat and deform the material due to heat.

For laser cutting acrylic, you need to set the power to a fixed level. Low power of laser cutter is needed while cutting a PETG material. The clear edge of acrylic is a unique feature and is not found very often.

This clear edge can be obtained by laser cutting the acrylic in the right way. It is also possible to get clear edges for PETG, but these materials risk tinting while using laser cut.

For acrylic, you can use any standard glue to do the bonding and it works perfectly. In PETG, you are limited to super glue and a few other bonding agents only. But we recommend the bonding of this material via mechanical fixing. When it comes to thermoforming, both the materials are suitable and both can be thermoformed. However, there is a slight difference. PETG does not lose its strength when thermoformed, but from experience, we have seen that sometimes acrylic loses its strength in the process of thermoforming and becomes fragile.

DIY Applications

If you’re a DIY-er, you’ll love to use acrylic plastic. It is one of the most used plastic materials on earth for DIY uses. Because of their lightweight, strong and most importantly, flexible nature, they are very easy to work with.

In addition, you can easily cut and glue acrylic pieces without a ton of knowledge or expertise. All these things make acrylic the best option for DIY projects.

Conclusion

Now that you know everything you need to know about PETG and acrylic, it’s time to make the right decision. Make your right decision considering the facts I have mentioned above. Keep in mind that acrylic plastics are flexible and can be used for curved purposes. If you are looking for a manufacturer of acrylic, UVACRYLIC will be the ideal one.

PETG is rigid and stronger than acrylic plastics, but it is scratch-prone. Last but not least, remember that PETG materials are not recommended for outdoor use. But you can use acrylic plastics for both indoor and outdoor purposes.