The Best Guideline Of Cutting Acrylic Sheet in 2025

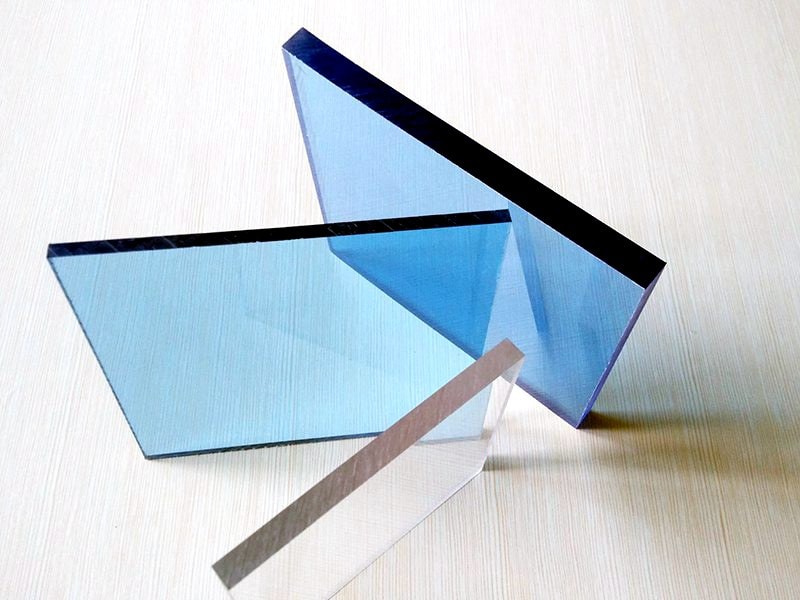

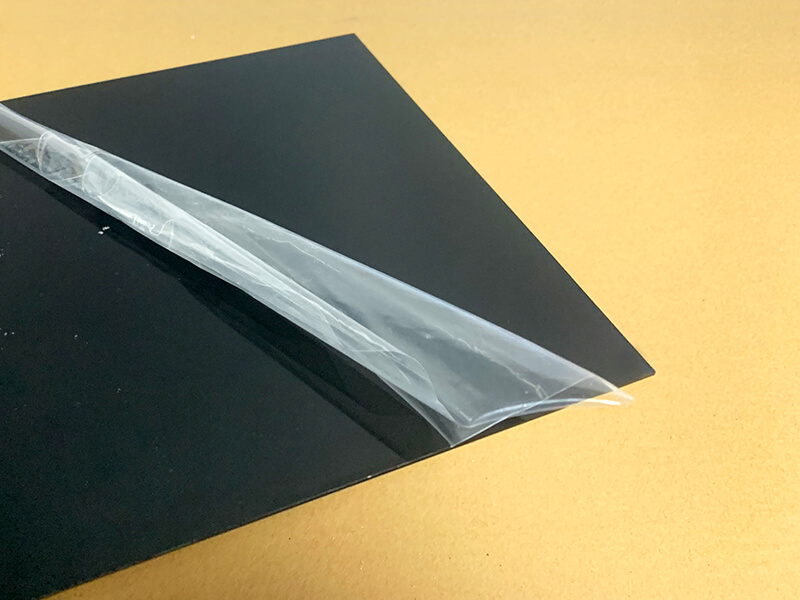

When we need to use acrylic material to make something, such as a box, it is often necessary to cut the acrylic sheet.

Even if you are buying ready-made acrylic products, it is difficult to ensure that it is perfect, for example, you want an acrylic fish tank embedded in the wall, then you will inevitably need to make some small cutting machining.

In this article, I’ll show you several ways to cut acrylic panels, you can choose the right one according to your actual situation, of course, the cutting process is sure to protect yourself not to get hurt.

How To Cut Acrylic Sheet With A Circular Saw

A Circular saw is a tool available for cutting acrylic sheets, if it is to cut a straight line, then use a circular saw is better.

This is very professional equipment, so we have to prepare before we start. You have to prepare:

First of all, you have to confirm the thickness of the acrylic sheet you need to cut. The blade used to cut thin plexiglass is different from the blade used to cut thick plexiglass. For thick plates, please use a carbide tip. These blades are more durable and sharper than other blades, so they are suitable for their work. For thin slices, choose a sharp blade.

When you are sure that everything is ready, we can start.

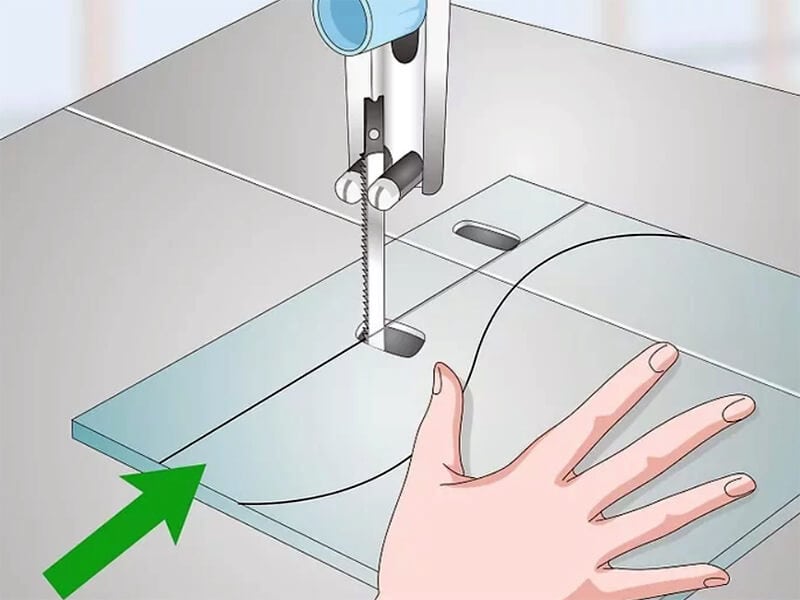

How To Cut Acrylic Sheet With A Jigsaw

You can also cut acrylic products through a jigsaw,In fact, the basic steps are similar to the previous method. When using this tool, in order to prevent chipping, there is a technique to stick the tape on the cutting line. To prevent the saw from tilting to the left or right during straight cutting, please using the clamp-type guide. This will give you a more professional appearance. Also, don’t forget the blades: find uncoated (ie unpainted) fine-toothed sheet metal puzzle blades. You can do some exercises on some scraps first, so let’s get started.

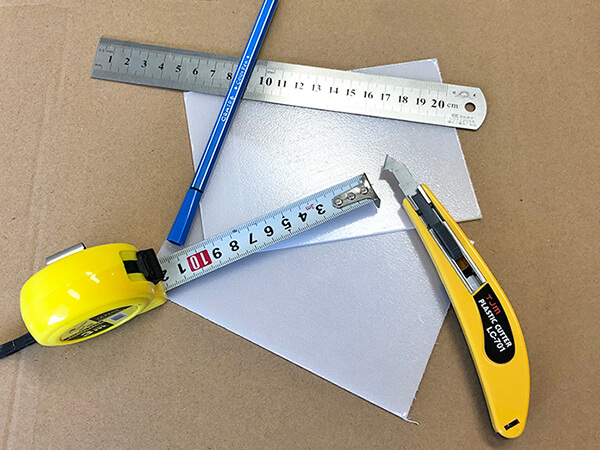

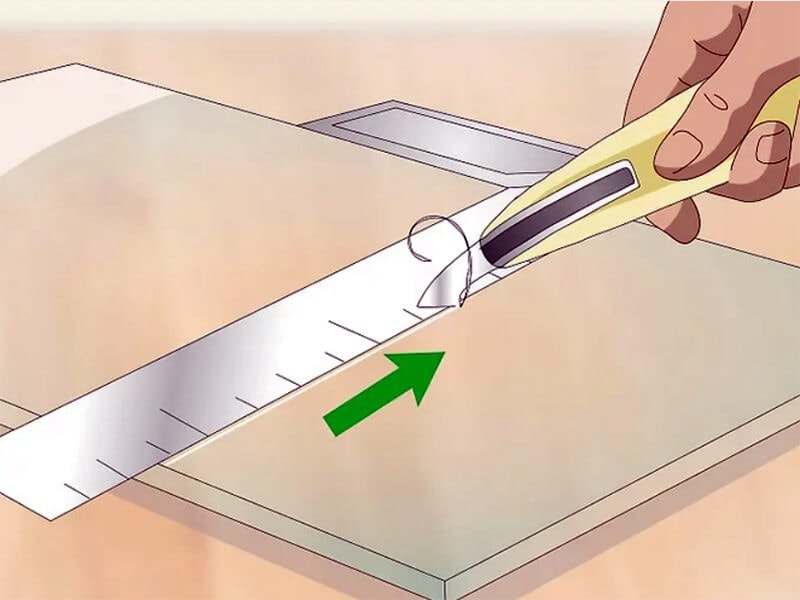

How To Cut Acrylic Sheet With A Knife

It is one of the easiest methods to cut acrylic tabletops. The process doesn’t demand to use of a power saw or any other heavy-duty electrical equipment. However, the process requires the following steps:

How To Cut Acrylic Sheet By Hand

Most people prefer to cut acrylic using a hand saw. However, this technique demands more concentration when compared with electrical saws. To achieve the best result it is advisable to use a saw that has uniform teeth.

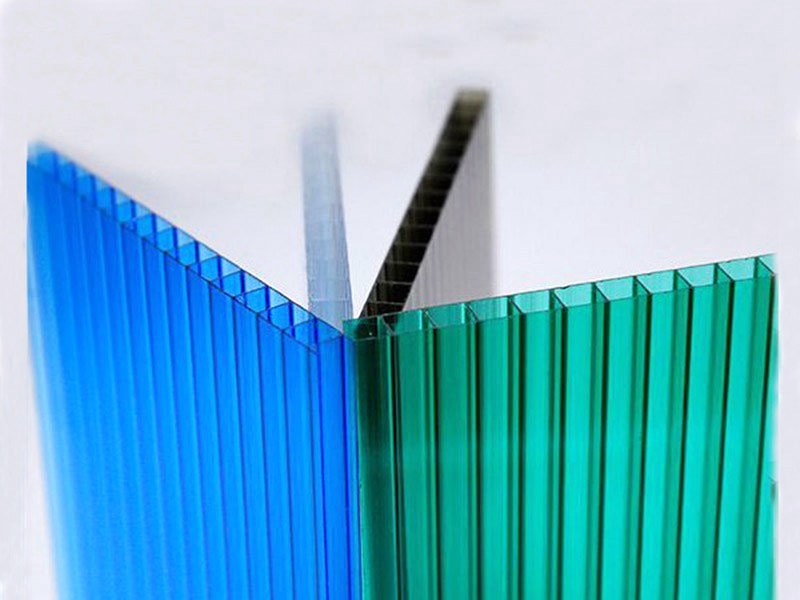

Cutting Acrylic Sheets With CNC

Like cutting polycarbonate sheets, you can cut acrylic with a CNC machine.

Conclusion

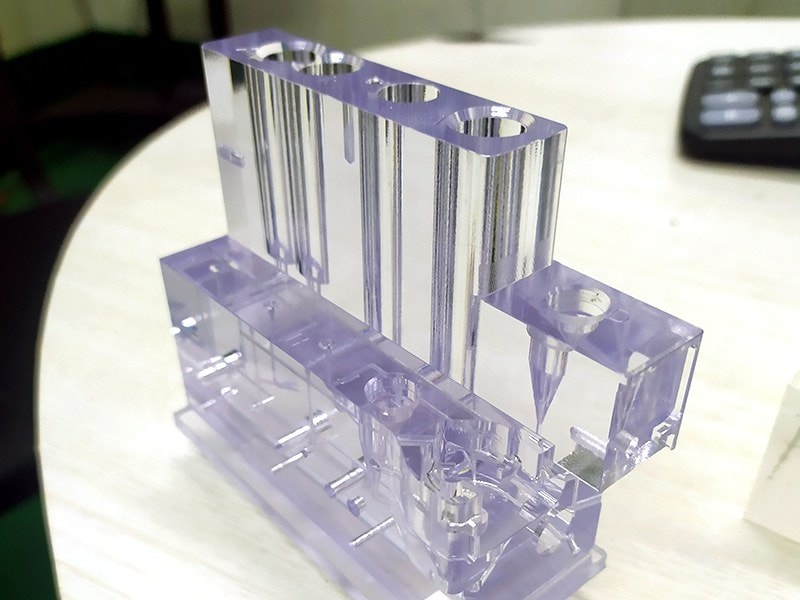

So, cutting acrylic is a very careful task, and you must protect yourself at all times. If you really need some special size acrylic sheets, you are welcome to consult us at any time, and we are happy to help you achieve your requirements. Maybe here, you want to know more about machining acrylic.

UVACRYLIC is a leading China acrylic manufacturer, if you want to know more about acrylic-based products, we are happy to hear from you.

Need a Supplier of Cutting Acrylic Service

About UVACRYLIC

UVACRYLIC is a 100% subsidiary of UVPLASTIC, which provides acrylic sheets, rods, and tubes in all forms, and provides machining acrylic service. If you are looking for an OEM factory of acrylic-based products, please feel free to contact us. The sister company is UVTECO, which is a supplier of engineering plastic and machining service.

Main Acrylic-based Products and Services

Need A Trustworthy Supplier Of Acrylic Product

Click on the button, you will find the Trustworthy Supplier Of Acrylic-based product and machining services.