How To Get The Best Use of Acrylic Plastic

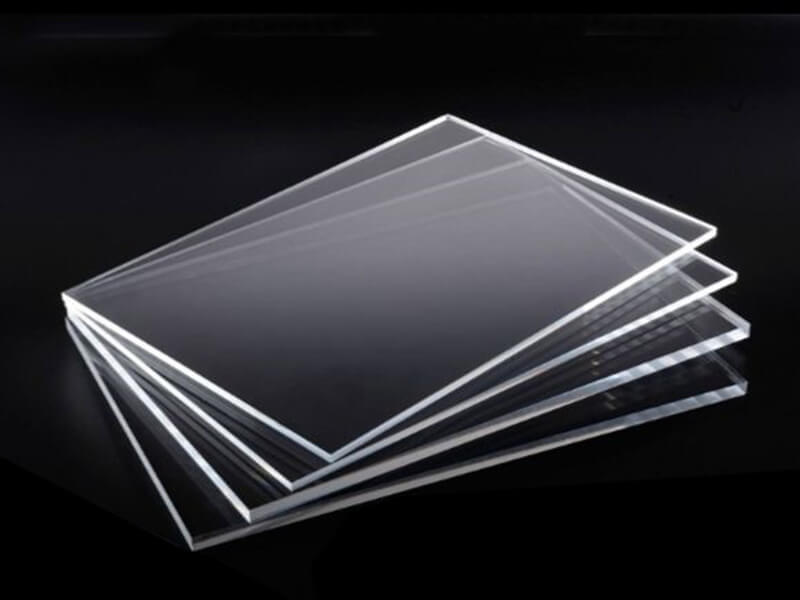

Acrylic plastics are now widely used because they are stronger than glass and an excellent alternative to glass. People are more convenient with acrylic plastics because of their qualities like lighter, stronger, weatherproof, transparent, clear, etc. Sometimes, people call it a plexiglass sheet.

Take an overview of the uses of this material. You will be able to have an idea about the durability and impact resistance of this material. Acrylic plastics are widely used as fish tanks, hockey rinks, shatterproof glass, skylights, etc. One of the significant advantages is that it is cost-effective.

Acrylic plastics provide you firmness and resistant qualities, this is also used by people because of the transparency. This is transparent, just like clear glass, but this is much stronger than glass and scratch-proof.

Learn the Basics of Acrylic

Acrylic plastics allow more light transmission than glass that is 92%. Also, this material is excellent at resisting heat and can stand up to 160°C. However, it softens when the temperature is raised high.

The acrylic is a transparent thermoplastic which commonly goes by the trade name- ‘plexiglass.’ You can use it as an impact-resistant material alternative to glass. Besides, this is half the weight of glass.

To know more about this material’s properties, we need to look at the usages of acrylic plastic. These plastics are used as roof panels for both homes and commercial places. Because they are impact and heat resistant and do not crack easily in extreme situations. Acrylic plastics are also used as lenses and screens. Because they are transparent, they make a great choice for lenses and screens. In the case of lenses, they can be designed into both concave and convex lenses as per the need.

Common Acrylic Sheets You Could Find In The Market

Maintaining Acrylic Plastic

Knowing how to maintain your acrylic increases the lifespan of your acrylic plastic. This material is better than glass, but you also need to take care of it if you want it to last long enough.

You need to clean the surface area of your acrylic plastic to maintain the surface gloss. You can clean that with a plastic cleaner and polish it occasionally, not very frequently.

But rubbing or polishing the acrylic plastic will generate an electrostatic force on the surface that creates dust particles. To get rid of that, wipe the surface with a damp cloth to eliminate the electrostatic force. Maintaining acrylic plastic has many more than only cleaning and polishing the acrylic. To keep your acrylic plastic long-lasting and expand its lifespan, you need to know how to maintain it. Check out below on how to maintain your acrylic plastic.

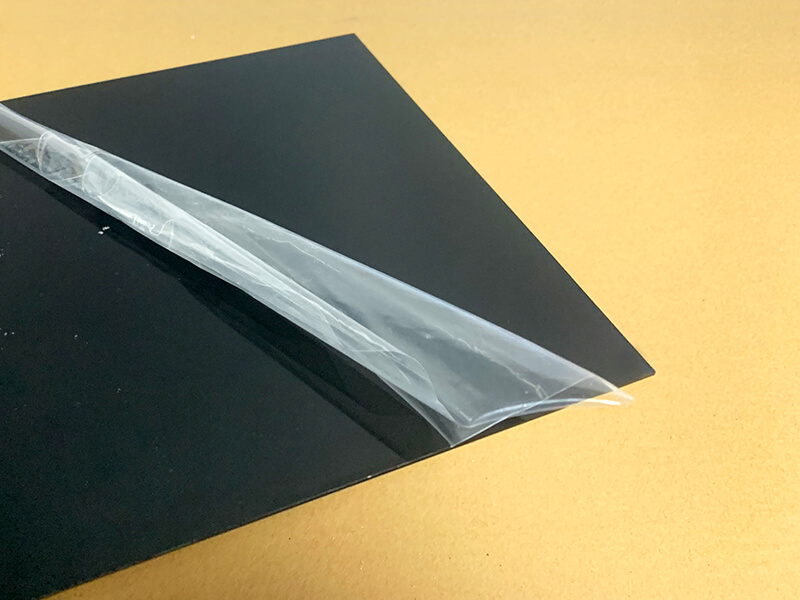

Handling Acrylic plastic

Before purchasing your acrylic plastic, know what your requirements are. Purchase according to your need.

After purchasing the acrylic plastic, you need to install it properly and fix it wherever you apply it.

If this is set on the roof, you need to fix it firmly because it has to face the harsh weather, and if not fixed securely, accidents might occur.

Make sure you’re following the proper practices while installing the sheets. So you don’t have to do it twice. You can do some practices or ask the supplier for some instructions before start install it.

Before installing the acrylic, make sure your chosen surface can support the acrylic plastic. I suggest taping the acrylic to the substrate, which indicates whether it can bear the load.

Cleaning Acrylic Plastic

The acrylic sheeting is very simple to clean, but you need to know some precautions before learning the cleaning process. The acrylic sheeting or material can be damaged by harsh or harsh solvents and cleaners.

When cleaning the acrylic sheeting, do not use ammonia, acetone, carbon tetrachloride, or gasoline as a cleaning solution.

Why not use them? Because they cause cracks in the acrylic sheeting and give it a frosted appearance.

So the ideal method to clean acrylic material is to use a mild soap or commercial plastic as the cleaning solvent. Clean the acrylic plastic and rub it gently with a non-abrasive lint-free or microfibre cloth to avoid scratches on the surface.

After cleaning it with the solvent, wash away the mixture with fresh water and dry the plastic to avoid water spots on it. Do not use any other solution other than water to wash out the dirt.

Cutting Acrylic Plastic

Acrylic sheets up to 3/16” can be cut by a method similar to glass. Use a scribing knife, a metal scriber, an awl, or a utility knife to cut the sheet according to how much you require. To cut with ascribing knife, draw the scriber 7-8 times along the straight edge held firmly in a place.

Then clamp or hold the sheet rigidly under a straight edge with the scriber hanging over the table. There are many methods of cutting your acrylic plastic to fit perfectly. Let’s jump into the detail:

Gluing Acrylic Plastic

Gluing the acrylic is also known as solvent welding. Gluing acrylic is not similar to gluing other household items that we usually join with glue. A powerful chemical called ‘acrylic cement is used to join the acrylic together.

The working mechanism of this glue is different. This softens the acrylic surface on which this is applied. When joined together, the two plates are softened, and they join together more like a bond. For this reason, this is called the adhesive solvent.

After attaching the two plates, make sure there is no gap left inside for proper bonding. Many prefer to apply the acrylic cement with a needle to apply precisely between the two plates. But the alternative way is to apply the cement on the part before joining or attaching it.

Bending Acrylic

Acrylic plastics are heated to make them bend. Heating the plastic softens the material, and it can be bent easily. Do not use a microwave oven for heating acrylic because it can emit explosive fumes and ignite.

Strip heather is the best tool for cooling acrylic. This tool forms straight line bends. Heat the sheet until it sags at the bend line. Sheets thicker than 3/16” should be heated on both sides.

Want to more methods about custom acrylic.

Where To Store Acrylic

As acrylic materials expand in contact with heat, do not store them under open sunlight. Avoid storing in extreme temperatures like above 100 degrees Fahrenheit. Keep it under the shade at average temperatures.

Conclusion

Now that you know all the necessary information about acrylic plastic, it’s time to place an order. If you’re looking to purchase them for any residential, commercial, or DIY projects, let UVACRYLIC help you regarding this matter.

UVACRYLIC is one of the leading manufacturers of acrylic and polycarbonate sheet. You’ll get the utmost quality and top lever customer service from us.

The best part? You can order online from our shop section as well! So make no mistake and start your projects today!

Need A Trustworthy Supplier Of Acrylic Product

Click on the button, you will find the Trustworthy Supplier Of Acrylic-based product and machining services.