Best Acrylic Mirror Sheet

From 0.8mm To 8mmThickness…

Top Supplier of Acrylic Mirror In China

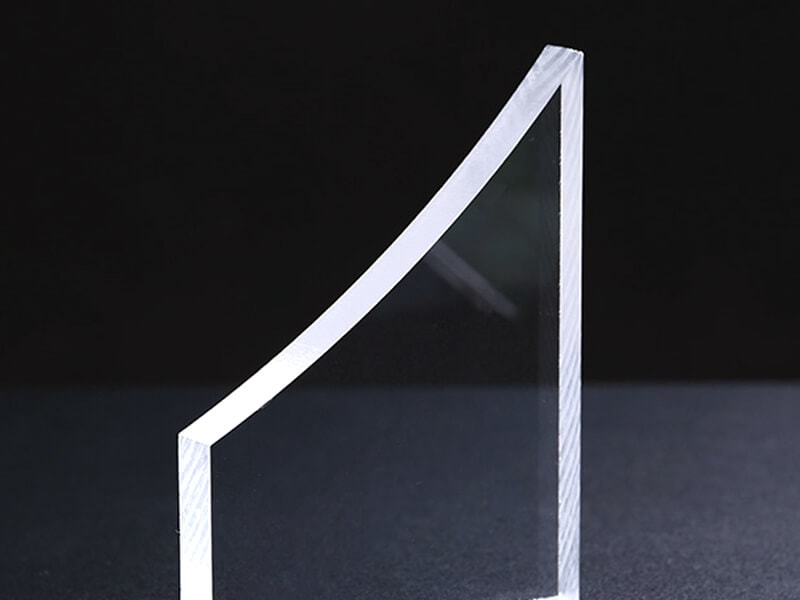

Acrylic Mirror Sheet is the ideal alternative to a glass mirror, meantime it offers more flexibility, higher shatter resistance, lighter weight, and excellent impact strength. Otherwise, Acrylic Mirror Sheet can be easily cut, bent, drilled, shaped, and thermoformed into various shapes. Therefore, Acrylic Mirror Sheet is the best material in environments where safety is paramount, for example, gyms mirrors, dance studios, and child-safe mirrors in playrooms.

UVACRYLIC is a leading supplier of acrylic mirrors in China, we offer more than 15 color options, the thickness is from 0.8mm to 8mm. We always use virgin raw material, purchased from Lucite and Mitsubishi company. With strict quality control, the annual production capacity is more than 20 thousand tons. Today, we are providing excellent clear acrylic sheets to more than 1200 clients from 40 countries.

Acrylic Mirror Sheet Details

Dimensions of Acrylic Mirror Sheet

| Product Name | Model | Thickness | Max. Width (mm) | Size (mm) | Standard Size (ft) |

|---|---|---|---|---|---|

| Acrylic Mirror Sheet | UVAC-MI | 1mm, 2mm, 3mm, 4mm, 5mm, 6mm | 1220mm | 1220×1830, 1220×2440 | 4×6, 4×8 |

| Polycarbonate Mirror | UVPC-MI | 0.25mm, 0.5mm, 1mm | 1220mm | 1220×1830 | 4×6 |

| PS Mirror | UVPS-MI | 0.8mm, 1mm, 1.2mm, 1.5mm, 1.8mm, 2mm, 3mm | 1220mm | 1220×1830, 1220×2440 | 4×6, 4×8 |

Cutting mirror is available;

The adhesive on back of acrylic mirror is available;

Physical Properties

| Properties | Unit | Value |

|---|---|---|

| Density (clear arcylic) | g/cm^3 | 1.19 |

| Tensile Strength | Mpa | >70 |

| Charpy impact strength (unnotched) | KJ/m^2 | >13 |

| Tension Modulus of Elasticity | Mpa | >3000 |

| Tensile Strain at break | % | >4 |

| Flexural strength | Mpa | 100 to 115 |

| Charpy impact strength (unnotched) | kj/m^2 | >17 |

| Vicat softening temperature | °C | >105 |

| Dimensional change on heating (shrinkage) | % | <2.5 |

| Total luminous transmittace | % | >90 |

| Rockwell hardness | 100 to 115 | |

| Linear expansion coefficient | K^ -1 | 7×10^-5 |

| Temperature of deflection under load | °C | 95 to 100 |

| Light transmittance | % | >90 |

100% Environment-Friendly PMMA Material

Purchased From Lucite And MITSUBISHI Company Directly