Best Acrylic Tube

Diameter from 3mm To 1500mm, Cut to size…

Top Supplier of Acrylic/Plexiglass Tube

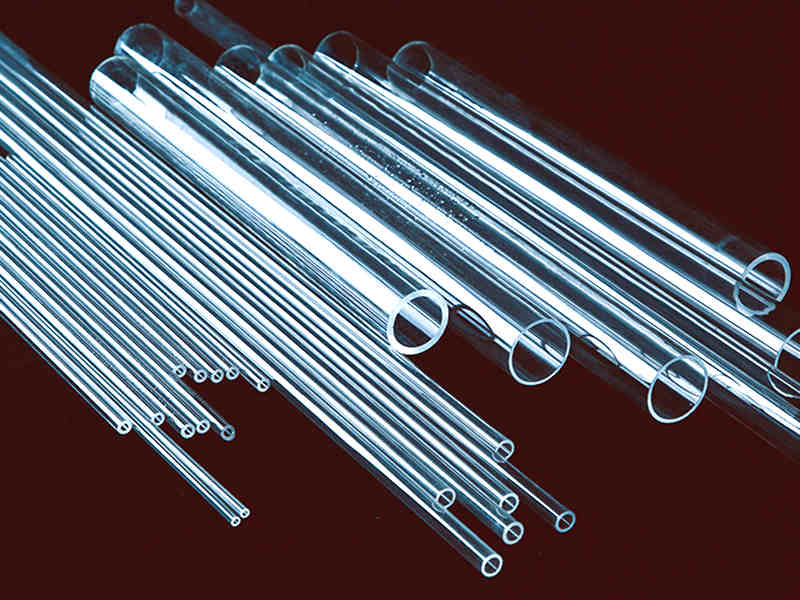

Acrylic Tube is an excellent clear plastic tube with wide color options such as transparent, translucent, opaque, and custom colors. It is also called “Plexiglass Tube“, “Acrylic Pipe” or “Acrylic Cylinder” in some countries. Plexiglass Tubes are manufactured by extrusion or casting process, the outside diameter is from 1/10 to 60 inches (From 2.5 to 1500 millimeters), wall thickness is from 1mm to 10mm.

The acrylic tube offers superior chemical resistance, UV resistance, and weather ability, they are the right material to replace glass tubes because it is crystal clear, lighter weight, more shatter-resistant and it is easier to work with. The main applications include the POP display, experimental equipment, home depot, teaching facilities, lighting equipment, and industrial application.

With more than 15 years of experience in this field, UVACRYLIC has grown to be a leading manufacturer of acrylic/plexiglass tubes in China and provides a wide diameter range and color options. Meantime, we provide the machining service for acrylic tubes to global clients including cutting to size, polishing, bending, and thermal-forming. Today, we are providing excellent clear acrylic tubes to more than 1200 clients from 40 countries.

Plexiglass/Acrylic Tube Details

Basic Information

| No | Item | Description |

|---|---|---|

| 1 | Product Name | Acrylic/Plexiglass Tube, Acrylic Cylinder |

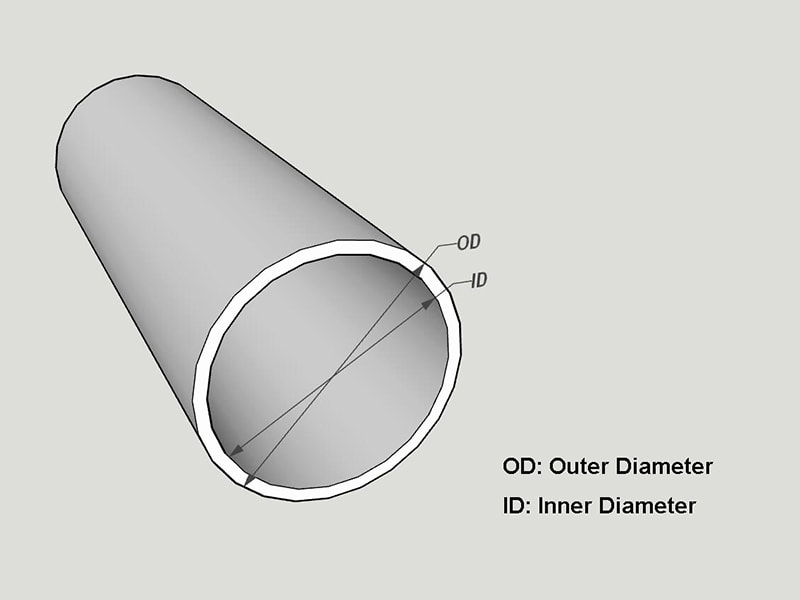

| 2 | Model | UVACT-OD-ID |

| 3 | Diameter Range | From 2.5mm To 1500mm |

| 4 | Standard Colors | Clear, Red, Yellow, Orange, White, Black, Purple |

| 5 | Custom Colors | Available |

| 6 | Standard Length | 1000mm, 2000mm, 5000mm |

| 7 | Custom Length | Available |

Diameter Range

Large Diameter Acrylic Tube

Physical Properties

| No. | Properties | Unit | Value |

|---|---|---|---|

| 1 | Density (clear acrylic) | g/cm^3 | 1.19 |

| 2 | Tensile Strength | Mpa | >70 |

| 3 | Light transmittance | % | >90 |

| 4 | Charpy impact strength (unnotched) | KJ/m^2 | >13 |

| 5 | Tension Modulus of Elasticity | Mpa | >3000 |

| 6 | Tensile Strain at break | % | >4 |

| 7 | Flexural strength | Mpa | 100 to 115 |

| 8 | Vicat softening temperature | °C | >105 |

| 9 | Dimensional change on heating (shrinkage) | % | <2.5 |

| 10 | Total luminous transmittace | % | >90 |

| 11 | Rockwell hardness | 100 to 115 | |

| 12 | Linear expansion coefficient | K^ -1 | 7×10^-5 |

| 13 | Temperature of deflection under load | °C | 95 to 100 |

Main Benefits

100% Environment-Friendly PMMA Material

Purchased From Lucite And MITSUBISHI Company Directly

REACH Testing Report

RoHS Testing Report

Related Products And Machining Services

Related Articles About Plexiglass Tube

Frequently Asked Questions

Need A Trustworthy Supplier Of Acrylic Tube

Click on the button, you will find the Trustworthy Supplier Of standard Acrylic tubes and machining services.