Applications of Plexiglass tube

Introduction

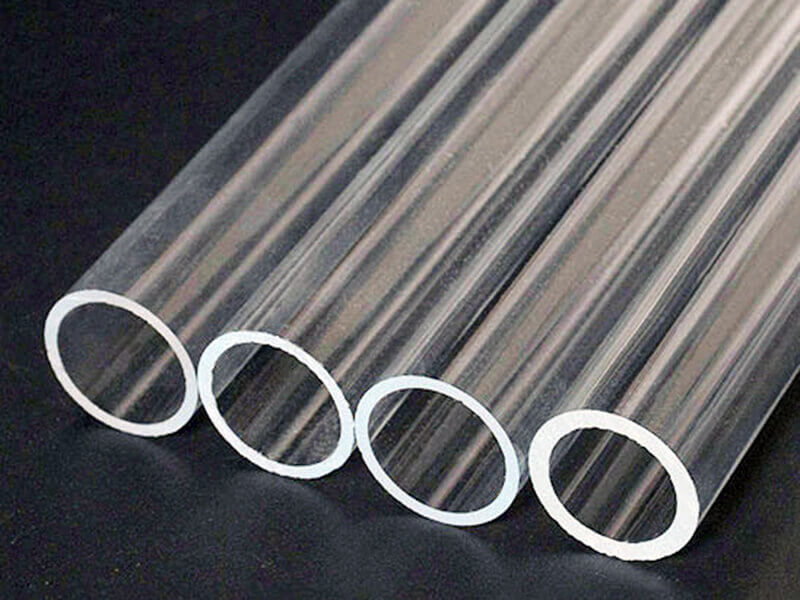

The flexibility, durability, and adaptability of plexiglass tubes make them suitable for industrial, commercial, and homes. Plexiglass tubes have gained popularity over steel, aluminum, and other materials because of their durability and cost-effectiveness since it is far less expensive to produce.

To better understand this material, we will now focus on some of the most common uses of plexiglass tubes.

Applications Of Plexiglass Tube

Machinery Industry

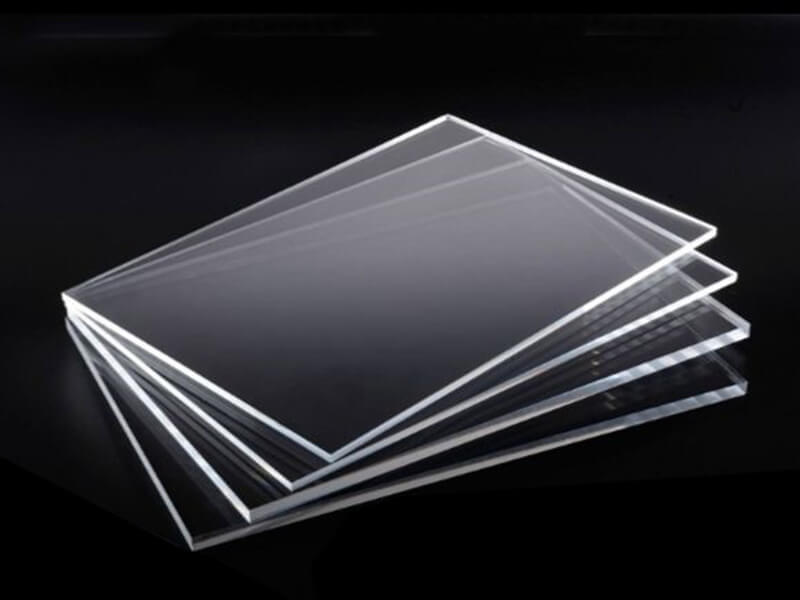

Like plexiglass sheets, as you’ve seen earlier, the outstanding durability makes it appropriate for industrial applications. Plexiglass is used to create dipper tubes which makes it a great fit for the machinery industry.

The industry emits gases and smoke using plexiglass vent tubes. The tubes are easy to maintain and don’t get pale often. They are also used to make the legs of shelves.

You can use Plexiglass tubes as shelf spacer legs too. Other plastics might not bear the weight and bend or get cracked, but as this plastic has good strength and is durable enough, you can use this as shelf spacer legs to bear the weight.

Because of its excellent clarity, plexiglass is used in industries as pneumatic conveyors. A pneumatic conveyor can move fine and dry materials using pressure differentials and a flow of gas (typically compressed air or nitrogen).

The plexiglass tubing is capable of handling the compression of the pneumatic system. It is ideal for outdoor applications since it can endure temperatures ranging from -4°F to 140°F. Plexiglass tubing is suitable for any environment or citation and it can withstand 115 PSI at 68°F.

Juice Dispensers

Plexiglass tubing is used as juice dispensers and you can serve large quantities of juice hygienically. More than one fruit or vegetable can be dispensed and served and the water particles do not get stuck inside the tube, which is an excellent quality of this material.

Because of its clarity and lightweight, it is used as a tube for juice dispensers, making it attractive to the guests and serving with ease. These are often used as parties for serving large quantities at a time. Traditional glass tubes seem very heavy compared to plexiglass tubes.

Automotive industry

The automotive industry is one of the most frequent users of this material. Plexiglass tubes are used as fuel lines and fuel fillers because of their flexibility and endurance. They are also used as ”L” sections in cars.

The new version of cars doesn’t follow the traditional methods anymore. Now plexiglass transparent tubes are used as a corrugated conduit in automotive industries. It is an excellent choice if you require flexibility and strength for the corrugated conduit, allowing you to see the interior.

This material is also used as spring retainers very often in the new version of cars. It is also used as a pipeline or tube for various cars for transferring oil or gas. One of the main reasons is that this material is flexible and has excellent strength making it appropriate.

Marine Equipment

As this material is used for automobiles, many marine equipment parts contain plastic. You must’ve seen the bilge pump tubing for boats. Many prefer transparent tubes using plexiglass tubing. The heavy-duty qualities of plexiglass tubing make it chemical and oil resistant.

Farming

This tubing is primarily used for water systems in farming. We recommend using it for water systems in farming because it is easy to install, durable, lasts a long time, and does not corrode or rust.

One of the great advantages is that unlike steel or aluminum piping, which is not flexible, you can run plexiglass tubing for hundreds of feet without any extra expense, such as adding joints or connectors.

Apart from water systems, they are used as tubing for pesticide sprays, pump tubes, turf core tubes, cover tubes for steel, dewatering tubes, support frames, etc. This comes at an affordable price for the farmers to afford.

Medical

Medical tubing delivers fluids to and from the body. It is commonly used in dialysis or sometimes while donating blood. The plexiglass tubes for medical purposes are made from small, complex, custom plastic extrusions.

Medical-grade tubes are produced in an isolated environment far away from any risk of contamination. They are produced with simple, dual, or triple lumens, cut to lengths, or made to reels. You can also have your custom tube just as you desire.

Construction

Because of their durability and light weight, plexiglass tubes have gained popularity for construction purposes. They are used as roof vent ducting, electrical cable ducting, fiber optic ducting, street lighting orange deduct, traffic signal orange deduct, etc.

They are also used as drain rods to drain out water and insulation tubes for electrical uses. Other uses include- space cords, high tension cover tubes, non-gas carrying pipe sleeves, and many more.

Sports and Leisure

These tubes are also used as golf ball collectors, fishing rod protection cases, flagsticks, rake handles, birdcage perches, hula hoops, and rainwater diverting tubes in your garden. Sometimes, people use polycarbonate tubing for these applications.

Electrical Plumbing

Plastic tubing is used for electrical plumbing and it works great! The plexiglass tubing is used for electrical cable conduit polypropylene. This protects the electrical wiring in a building or structure. You don’t need extra connectors or joints for the pipelines to connect since the plastic tubing is very flexible.

Plexiglass tubing is used for many purposes but the most common uses we see daily are Polypropylene Push Fit Waste Pipes, PVC and ABS Solvent Weld Waste Pipes, Fibre Optic Ducting (up to 500m coils), Electrical Cable Ducting in Coils/Sticks, Hot and Cold Water Pipe Duct, Single-wall Flexible Small Bore Corrugated Duct HDPE, etc.

Conclusion

Now that you read everything about the applications, you know more about this material and how well it serves. Plexiglass tubes are manufactured differently for different applications. One grade tubing is not suitable for all purposes. They are manufactured based on what you need them for.

Plastic tubing has gained a reputation over metal tubing because they do not corrode or rust. Another major advantage is that they are flexible and can save expenses for joints. They do not need to be fixed at one point. Rather they can be used for portable use.

UVACRYLIC is a leading supplier of acrylic tubes, the diameter is from 3mm to 1500mm, custom colors are available. If you need it, please feel free to let us know.