Can you bend the acrylic tube?

Know More About Acrylic Tube

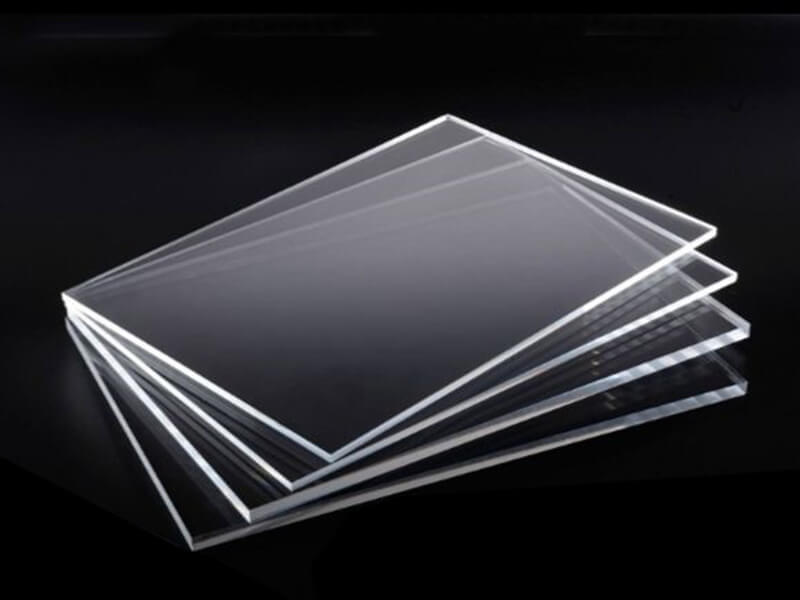

Among the many acrylic products, the most familiar ones are generally acrylic sheets, right? So here we will introduce you to another acrylic product: acrylic tubes.

Acrylic tubes are actually very widely used in real life. In addition to signs, POP displays, and glass tube substitutes, they can also be found in many toys and home furnishings. In addition, many professional fields, such as scientists and medical professionals, also use acrylic tubes for surgical equipment, biomedical equipment, and laboratory equipment. You can also find acrylic tubes in architecture, art, and many seemingly difficult project designs.

How strong is the acrylic tube?

I think one thing is very clear to everyone: Acrylic is very strong compared to common glass, but not stronger than polycarbonate tubes. Of course, because of the fragile nature of glass itself, almost most materials can be stronger than glass. So, how strong is acrylic?

Acrylic tubing is 11 times stronger than glass, which makes for reliable and strong installations.

How do you make clear acrylic tubes?

As mentioned earlier, the acrylic tube has a very strong character, you can use it to complete many wonderful ideas, but I think sometimes you need more than an acrylic tube, you can also add a flat Or a round base, so you can make a chemical test tube by yourself, perfect. Of course, you can buy acrylic tubes in any store, but if you only need one or two occasions, I think you can consider your own DIY, which will save money. if you want a large number of acrylic tubes, I suggest you go to a professional manufacturer to buy it.

We will not introduce the professional method of making acrylic tubes here because it can be realized by the advanced equipment of the factory. Here, we only talk about the simple DIY method that can be completed, but it is inevitable that there will be some rough DIY methods.

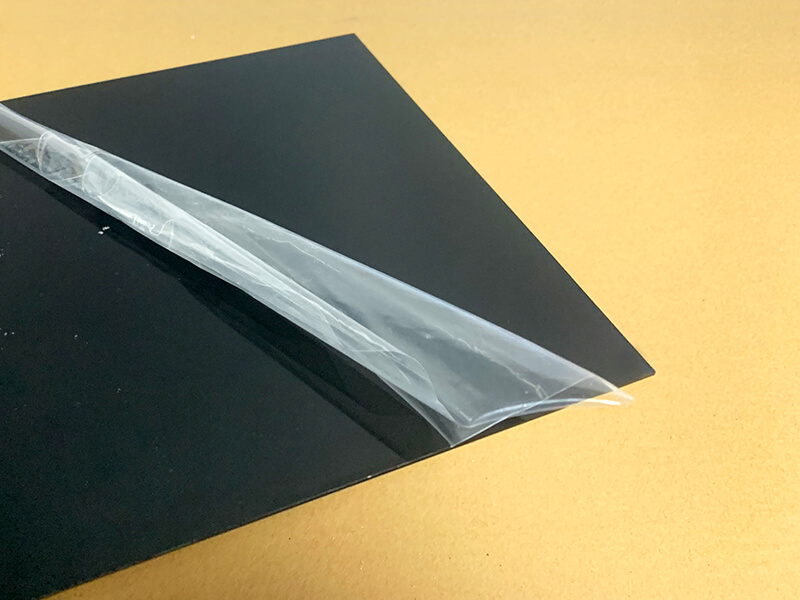

First of all, I think everyone is well aware that the acrylic tube is a cylindrical and hollow product, so the easiest way to come to mind is to bend an acrylic plate into a cylindrical shape and then connect it in a certain way. The seams are glued together, right?

So how to bend the acrylic sheet? You can click on this article to read it in detail.

How do you bend acrylic tubes?

When you use an acrylic tube, it is inevitable that there will be times when you need to bend it to achieve a certain purpose. So, how do you bend an acrylic tube?

One thing to confess to you is that the acrylic tube is harder and not as easy to handle as PVC material. It needs a “thermoforming” process to bend it. Simply put, the acrylic tube needs to be heated to soften it. Then, press to make it close to the mold surface to obtain the same shape as the mold surface. After cooling and shaping, the elbow can be completed. It’s easy to say, but it’s still a bit difficult to actually operate it. Do you need to be psychologically prepared?

The materials you need: Acrylic tube, Glue strip, Hot air gun

- Acrylic tubes are prone to deformation under extremely high-temperature conditions, which is the so-called kinking of pipes. Therefore, to prevent this deformation from damaging the acrylic tube, we need to fill the hollow tube or even use sand. However, we still recommend using adhesive strips, which are more convenient. Then, you need to prepare a suitable-sized adhesive strip so that it can be perfectly embedded in your acrylic tube.

- Use a heat gun to heat the acrylic tube and place the heat gun on the table vertically. Note that the temperature does not need to be too high. If the temperature is too high, the acrylic tube will produce bubbles, so the temperature should be controlled between 160 degrees Celsius and 270 degrees Celsius. During the heating process, do not stay in the same area for too long. Rotate the acrylic tube left and right to make it evenly heated, otherwise there will be bubbles inside the acrylic tube.

- Bending the acrylic tube according to the actual situation also requires continuous heating. Pay attention to uniform heating. This step depends on your hand control.

- Wait for the acrylic tube to cool down and take out the rubber strip.

Such a complete bend the acrylic tube process is over, and we look forward to your successful work!

Conclusion

In summary, bending acrylic tubes is a work that requires patience and meticulousness. If you want to be lazy, then you can choose to buy our acrylic tube directly.

About UVACRYLIC

UVACRYLIC is a leading manufacturer of plexiglass sheets in China, and we also provide custom acrylic. The parent company is UVPLASTIC, which is a leading manufacturer of polycarbonate sheets in China, meantime, provides machining polycarbonate service. If you have any questions about engineering plastic, please feel free to contact us.

Related Blogs

Related products