Custom Acrylic Windshield

You should see windshields everywhere in your daily life. They may be used as screen-like shields. They may be professional windshields for cars and boats. Can these windshields be made of acrylic sheets?

Can acrylic be used as a car windshield?

The use of high-quality plastic windshields has benefited almost all walks of life. In addition to being used in ordinary life, for example, if you want to go to your small garden to bask in the sun but do not want to get the wind, you may need one like this From a professional industry perspective, various companies have been able to take advantage of the increased durability, convenience, and convenience of customized plastic windshields. For example, construction workers can use plastics as windshields in bulldozers and other heavy equipment. It can also be used in agricultural and forestry equipment, forklifts, recreational vehicles, and golf carts. In addition, certain plastics (such as polycarbonate) have the ability to resist high impacts and can even be used in military and armored vehicles.

Among all kinds of plastics, there is no doubt that acrylic can be used in life without any problems, so can it be used as a windshield for a car?

The earliest cars did not have this kind of glass due to their slow speed. With the development of automobile technology, the speed has gradually increased. Wind and small debris hitting the driver’s face have become an increasingly serious problem. To reduce this trouble, the manufacturer added a piece of glass to the car, which is called a windshield in text.

Automobile glass mainly plays a protective role. It is mainly laminated tempered glass and tempered glass in the interlayer area, which can withstand strong impact. When shattered by impact, the glass will split into small pieces with blunt edges, which will not easily cause damage to the occupants. The cracks of the new type of regional toughened glass can still maintain a certain degree of clarity, ensuring that the driver’s field of vision is not affected.

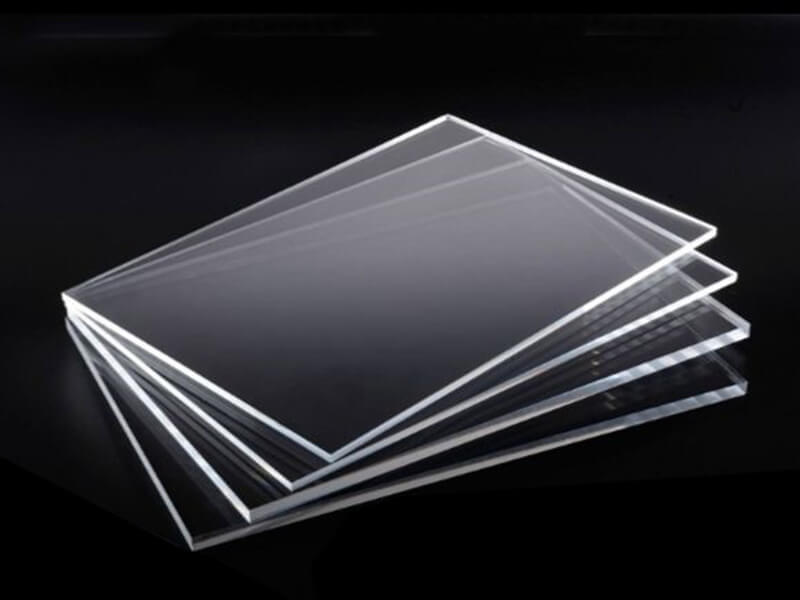

The acrylic sheet is a transparent plexiglass sheet with a light transmittance of more than 92%. If it is applied to automobile glass, it needs to be made through a special process, which cannot be supported by ordinary acrylic sheets.

Benefits of using acrylic windshield in your life

Although there are some extreme cases where our acrylic cannot be used, safety is still the most important thing. In our daily lives, we can use acrylic as a partition glass.

Custom acrylic windshields are known for providing excellent visual clarity. In fact, they are more transparent than traditional glass, making the material ideal for applications that require high visibility. This is also a very economical solution, and its cost is usually lower than that of glass and many other types of plastics, while still having sufficient impact resistance, durability, and strength.

Acrylic is also known for its resistance to most scratches and visual defects. Moreover, if the material is completely ground away, it can be easily polished back to a smooth surface. When exposed to ultraviolet light, it will not fade or turn yellow. Therefore, it may be a popular choice for those who want to use it outdoors.

How to make a windshield from an acrylic sheet

A windshield makes a sitting area in the garden or a terrace much more useful. When the sun first shows itself in the spring, but it is still too cool to sit outside, a windshield provides a pleasant shelter for sitting outdoors. It is not difficult to make a windshield, but you must take the foundation and mounting of your windshield into account. In this blog, we can teach you how to make a windshield from an acrylic sheet.

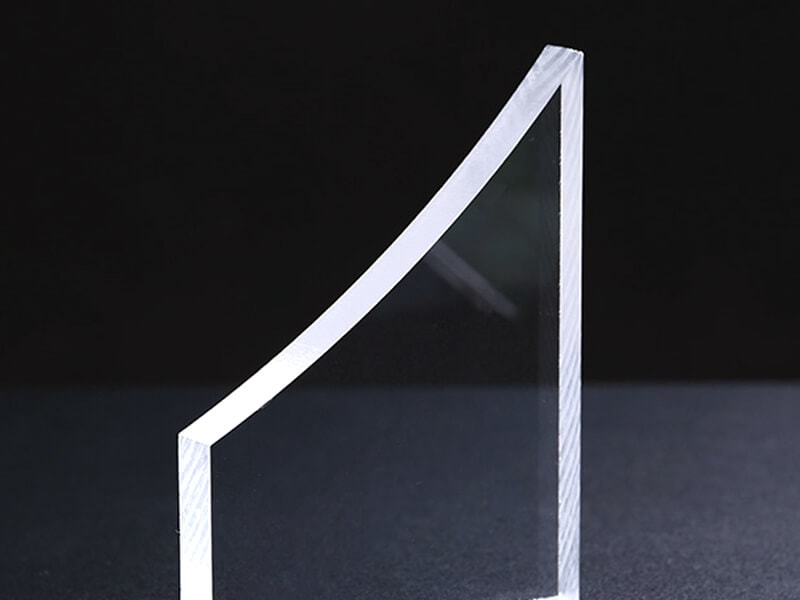

Acrylic is an ideal material for a windshield, it is 30 times stronger than glass and also much lighter. Acrylic is available in a clear version, in a range of colors, and also in opal white. The latter version is not transparent, but it does let light through. Acrylic is UV-resistant, but make sure you opt for cast acrylic. The extruded version has more internal stresses and will break more easily during machining. Of course, you can also combine different colors, this gives a quirky and playful effect. Before you start building a windshield, you must take the wind strength into account, which is largely determined by the location where you want to build the windshield. If this is in an open space, then the frame and the foundation must be strong. If your windshield comes close to an existing building, the foundation does not have to be as solid. We always advise you to err on the side of caution and make the foundation strong in any case.

Step 1: Lay the foundation

Even if we want to DIY a windshield, we must not be perfunctory, if you want the finished product to last longer.

You need to first think about how big the windshield you want. Imagine that there is an acrylic board sandwiched between two upright wooden stakes. Then this wooden stake must be hard enough. You can ask others for help to put the wooden stakes. It’s perfectly smashed in, but please remember that the two wooden stakes must be flush to look good.

Step 2: Buy acrylic sheet

You need to choose a clear acrylic sheet for your windshield. As we said, you must have planned the size of the acrylic. Please ensure that this size is suitable. Even if it is large, it cannot be small. After all, we can also cut the acrylic sheet if it is large. It will be very troublesome, so don’t forget that we have driven the stakes in.

The thickness of the acrylic sheet is also an aspect you need to consider. Where do you want to put this windshield? How is the wind there? If you are inaccurate in this judgment, you can consult us.

UVACRYLIC is a leading manufacturer of acrylic sheets in China. In the meantime, it provides custom acrylic with an integrated machining solution.

Step 3: Assemble

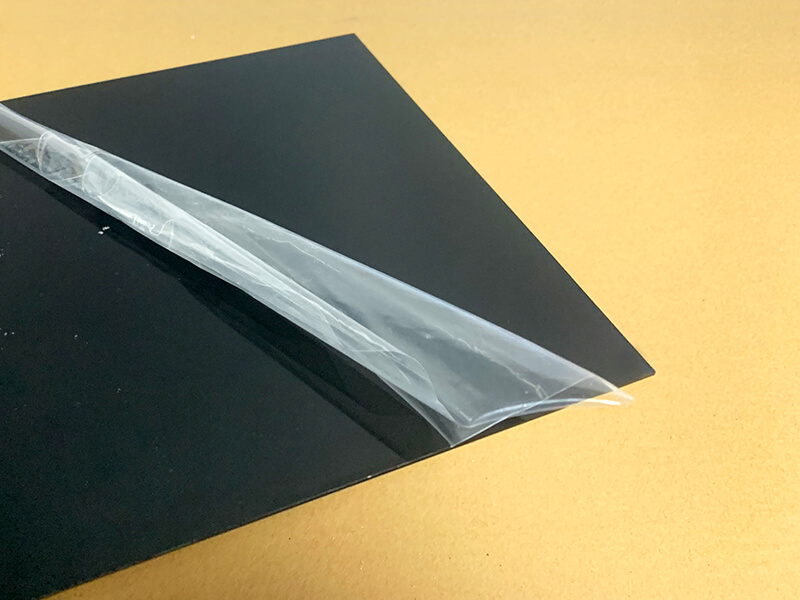

This step involves sandwiching a board between two wooden stakes. It is not difficult. As long as you can align the board, remember to tear off the acrylic protective film. This step involves sticking acrylic and wood together.

Step 4: Finishing off the construction

After the panels have been installed, you can finish the windshield. Mounting a wooden beam on top nicely holds the panels in position, giving your windshield extra strength. You might also consider supporting the screen in the middle and at the end for even more strength.

Step 5: Preserving acrylic sheet

We strongly recommend preserving the acrylic so that it stays beautiful for longer and is easier to clean. This agent cleans the surface and makes the acrylic antistatic, keeping your windshield clean for longer and making it easier to clean.

Difference between polycarbonate and acrylic windshield

Polycarbonate sheets are 20 times stronger than plexiglass sheets, so they are also a good material for the windshield. If you hope your windshield offers a bulletproof function, polycarbonate will be the better choice. UVPLASTIC is the parent company of UVACRYLIC, which is the top manufacturer of polycarbonate sheets in China and provides machining polycarbonate service. If you are looking for a polycarbonate windshield or OEM factory, please contact UVPLASTIC.

Conclusion

Acrylic is just a category of plastics. Naturally, it is not omnipotent. We just have to use it in places where acrylic is suitable, right?

If you have any scenes in your life that need partitions, windshields, etc., I hope you can consider using acrylic to complete them at any time. If you have any questions, you can contact us.

Related Blogs

Related products