Best Clear Acrylic Sheets

Thickness from 0.8mm to 50mm, Cut to size…

Top Supplier of Clear Acrylic Sheet in China

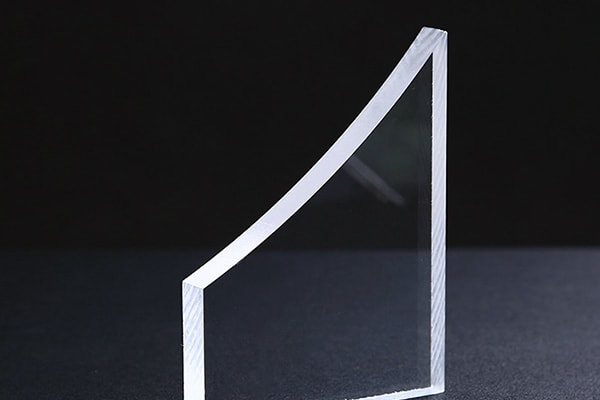

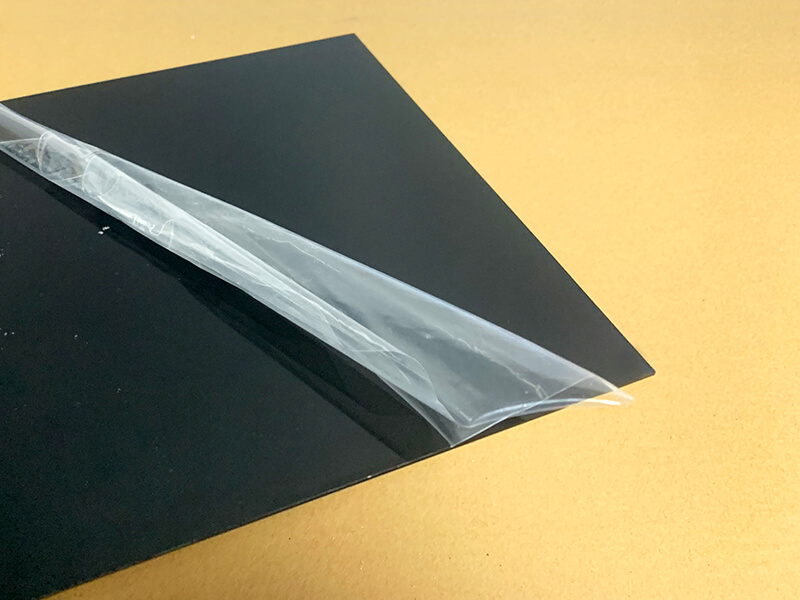

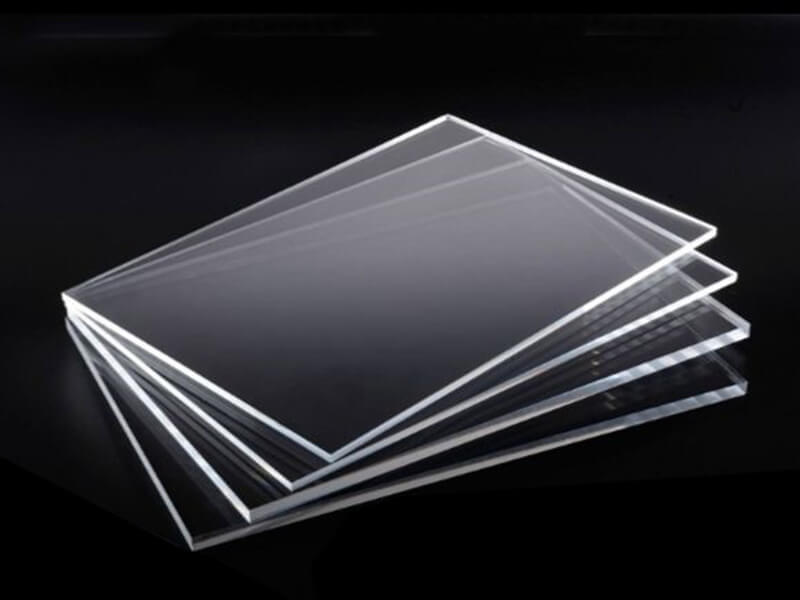

Clear Acrylic Sheet is a transparent thermoplastic sheet manufactured by the casting or extruded process. It isn’t affected by humidness and moisture, meantime, it offers optical clarity, a high strength-to-weight ratio, excellent light transmittance, and rigid surfaces. It is also called clear plexiglass sheet, acrylic glazing, or acrylic glass in some countries.

As an economical and general-purpose plastic sheet, the clear acrylic sheet offers a polished surface or frosted surface. The thicknesses are from 0.8mm to 50mm, standard sizes are 1220*2440 mm (4*8 ft) and 2000*3000 mm. Clear plexiglass offers excellent processability and can be easily cut, glued, thermoformed, and printed. It is widely used for home decoration, industrial applications, electron industry, POP display, packaging industry, construction industry, etc.

UVACRYLIC is a leading manufacturer of acrylic including cast and extruded acrylic sheets in China. We always use virgin raw materials, purchased from Lucite and Mitsubishi company. Meantime, we provide custom acrylic and OEM service with an integrated machining solution. After over 15 years of continuous effort, our annual production capacity is more than 20 thousand tons. Today, we are providing excellent acrylic sheets to more than 1200 clients from 40 countries.

UVAC-CL Clear Acrylic/Plexiglass Sheet Specification

Dimensions of Clear Acrylic Sheet

| Item | Model | Thickness Range (mm) | Size (mm) | Surface Type |

|---|---|---|---|---|

| Extruded Clear Acrylic Sheet | UVAC-EX-CL | 0.4mm, 0.5mm, 0.65mm, 0.8mm,1mm, 2mm, 2.5mm, 3mm, 4mm, 5mm, 6mm, 8mm, 10mm, 12mm, 15mm, 20mm | 1220×2440, 2000×3000, Custom Size | Polished surface |

| Cast Clear Acrylic Sheet | UVAC-CA-CL | 2mm, 4mm, 5mm, 6mm, 8mm, 10mm, 12mm, 15mm, 20mm, 22mm, 25mm, 30mm, 35mm, 40mm, 45mm 50 mm | 1220×2440, 2000×3000 | Polished surface, Frosted surface |

Thickness From Metric System To British System

| 0.06″ = 1.5mm | 0.31″ = 8mm | 1″ = 25mm |

| 0.08″ = 2mm | 0.39″ = 10mm | 1.18″ = 30mm |

| 0.128″ = 3mm | 1/2″ = 12mm | 1.37″ = 35mm |

| 0.157″ = 4mm | 0.59″ = 15mm | 1.57″ = 40mm |

| 0.196″ = 5mm | 3/4″ = 18mm | 1.77″ = 45mm |

| 1/4″ = 6mm | 0.787″ = 20mm | 2″ = 50mm |

What You Need To Know

Physical Properties

| Properties | Unit | Value |

|---|---|---|

| Density (clear acrylic) | g/cm^3 | 1.19 |

| Light transmittance | % | >90 |

| Tensile Strength | Mpa | >70 |

| Charpy impact strength (unnotched) | KJ/m^2 | >13 |

| Tension Modulus of Elasticity | Mpa | >3000 |

| Tensile Strain at break | % | >4 |

| Flexural strength | Mpa | 100 to 115 |

| Charpy impact strength (unnotched) | kj/m^2 | >17 |

| Vicat softening temperature | °C | >105 |

| Dimensional change on heating (shrinkage) | % | <2.5 |

| Total luminous transmittace | % | >90 |

| Rockwell hardness | 100 to 115 | |

| Linear expansion coefficient | K^ -1 | 7×10^-5 |

| Temperature of deflection under load | °C | 95 to 100 |

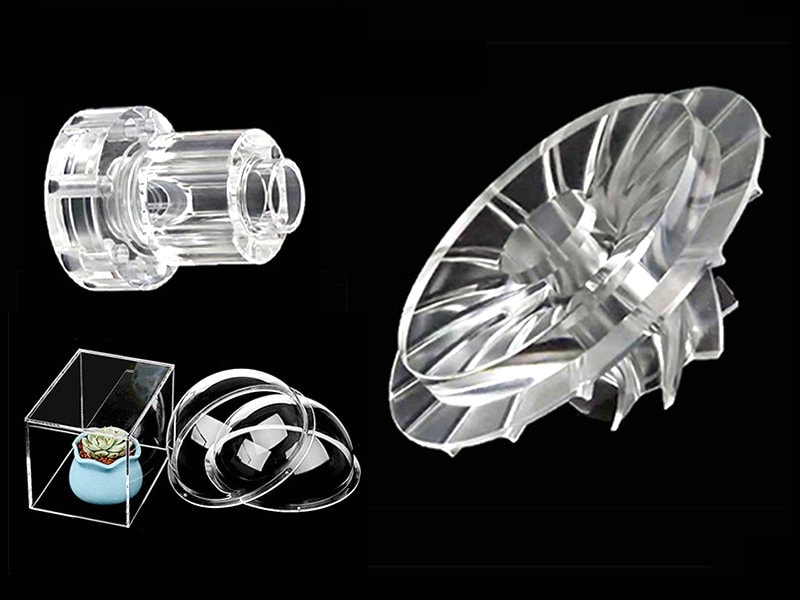

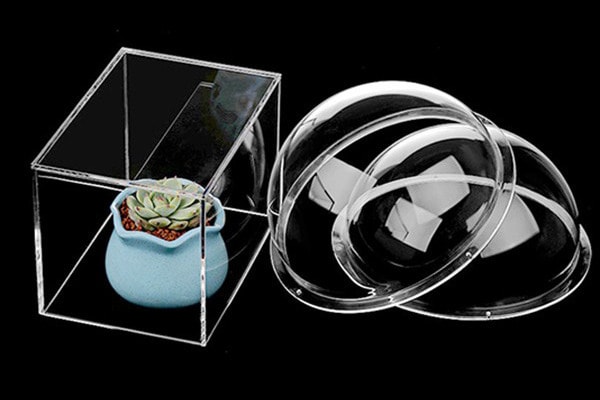

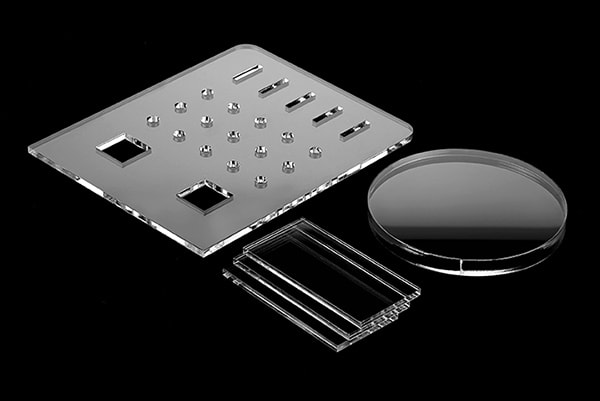

Machining Custom Acrylic Service

With more than 15 years of experience in machining acrylic, UVACRYLIC provides integrated machining solutions for custom acrylic. Today, we have grown to be the top OEM factory of acrylic-based products.

The common machining acrylic methods include cutting, polishing, bending, gluing, coating, CNC Machining, Printing, Drape forming, Injection Molding, Blow Molding, etc.

From common machining, methods, our engineers always find the right solution for all acrylic-based products.

Applications

100% Environment-Friendly PMMA Material

Purchased From Lucite And MITSUBISHI Company Directly

REACH Testing Report

RoHS Testing Report

Main Benefits Of UVAC-CL Clear Acrylic Sheet

Related Products And Machining Services

Related Articles About Clear Acrylic/Plexiglass

Frequently Asked Questions

Need A Trustworthy Supplier Of Acrylic Sheet

Click on the button, you will find the Trustworthy Supplier Of standard or custom clear Acrylic Sheets.