Introduction of PMMA Injection Molding Process

Before diving deep into the topic, let us understand what PMMA and injection molding is. PMMA is an abbreviation of (poly-methyl methacrylate) which is commonly known as acrylic or plexiglass sheet. At the same time, injection molding is a manufacturing process of shaping plastic where a heated material is injected into a mold to give it a shape.

PMMA injection molding is a very effective manufacturing process for creating high-quality plastic prototype. In this process, PMMA or acrylic is heated at its melting point. When it is liquified, it is injected into a high-pressure mold to give it the desired shape.

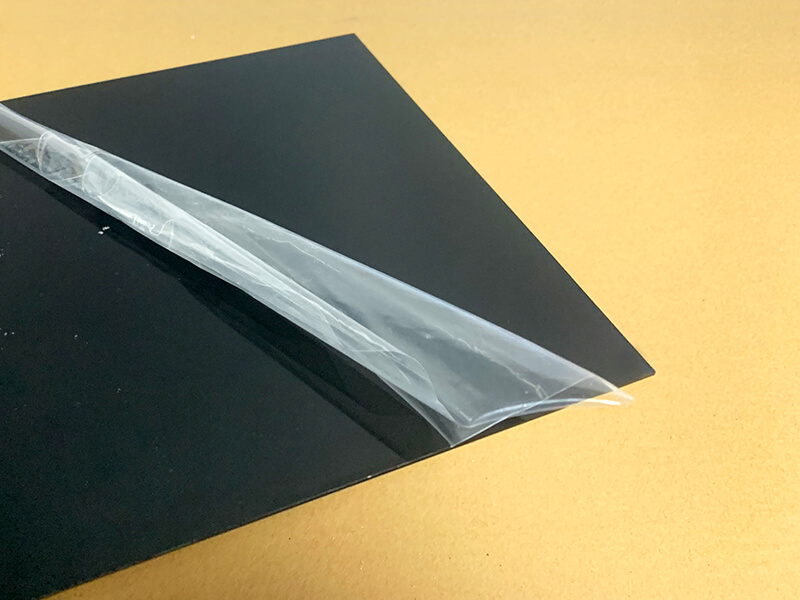

PMMA Injection Molding

PMMA injection molding is a very popular and effective injection molding process for manufacturing different parts and prototypes. This process is used in various industries like- electronics, manufacturing, the automobile industry, etc.

If you are looking for prototypes in haste, then you can go for 3D prototypes. However, if you want reliable and high-quality prototypes, you should go for plastic injection molding. You should know that, when it comes to high volume production, injection molding is a very expensive and non-reliable process. In contrast, prototyping for low volume production is a reliable and wise option.

How PMMA Injection Molding Works

Design of Parts

Injection molding has many steps until a final step is fabricated. The first step is the design of the part. In the beginning, you have to determine the feasibility of the product and its production to determine the design.

Engineering Phase

After working on product design, the parts have to be engineered to be easily produced in steel or metal dies. Finally, these parts are drafted and designed to be easily cooled and ejected from the molds.

In this process, the engineers have to be careful in wall thickness and proper design so that acrylic prototypes don’t get trapped during ejection. In addition, ensure that there is a proper place for the gate for injection of molten material and analyze the proper flow of molten material after injection.

Geometry of Molds

The mold includes pins that help in the ejection of parts after their formation. It also provides water flow inside the mold to help cool molten materials in the mold. The mold design for injection molding is first drawn on a computer called computer-aided drawing.

Why PMMA or Acrylic is Mostly Used for Injection Molding?

PMMA or acrylic is a thermoplastic with excellent impact resistance, weather resistance, and lightweight. It is preferred over polycarbonates because of its ease of the process, low cost, flexibility, durability, etc. Maybe, you want to know what is acrylic.

Acrylic is a thermoplastic, which means it can be melted at its melting point and easily cooled again to the original state. This feature of acrylic makes it perfect for PMMA injection molding processes.

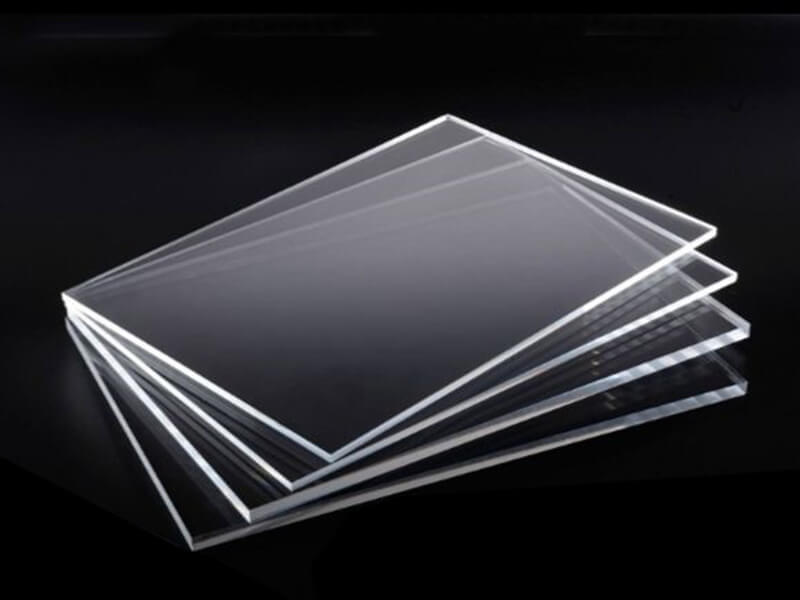

Before the discovery of PMMA prototypes, prototyping was a difficult task and it required a lot of effort and expenses to fabricate metallic prototypes and polycarbonate. In addition, these materials are also harmful to human health as they contain bisphenol-A. Acrylic is now in demand for fabricating flexible, lightweight, and scratch-resistant. In addition, acrylic is a widely used material and a perfect substitute for glass.

Uses of PMMA Prototypes

PMMA or acrylic materials are in demand for any industry looking to develop a stronger but cheaper alternative to glass. However, before knowing about a few applications of PMMA plastics, let us first know about their uses.

Perfect Substitute of Glass

PMMA clear plastics have excellent clarity and are stronger than glass. PMMA is also commonly used as a viewing port. This material is highly flexible, durable and available at a low cost. This is also used as pressure hulls for deep-sea submersibles.

Because of acrylic’s excellent clarity, this is used as lenses and backlights of automobiles. Glass can easily crack and is not flexible, unlike acrylic plastics.

Since it gives better protection against thrown objects, many safety vehicles like riot control or police vehicles, use acrylic as the main material for the windows.

Futuristic Looks

To grab the attention of people, many automobile industries, furniture showrooms, manufacturing companies showcase their upcoming models made up of acrylic plastics to show the futuristic look of the piece.

Medical Industry

PMMA prototypes are widely used in the medical industry too. Contact lenses and eyeglasses are often made up of acrylic as they are less brittle than glass. PMMA has good compatibility with human tissue. Therefore, it is used for the treatment of cataracts.

Parts made with this material are also used in bioprocess chromatography, treatment of diseases like tuberculosis, cosmetic surgeries, etc.

The applications of PMMA prototypes include

Advantages Of PMMA Injection Molding

You can use acrylic parts in both traditional machining and injection molding because of their features. However, injection molding has separate advantages compared to other machining and processes. The advantages of Injection molding are described below:

Conclusion

Now that you know everything about injection molding, you know your solution. Remember, the primary step is to make a design of the mold. The mold gives structure to the PMMA molten after cooling it. The injection molding process gives you the exact copy of the material you desire and all the pieces are produced in equal size and shape. Therefore there are no errors in this process.

About UVACRYLIC

UVACRYLIC is a subsidiary of UVPLASTIC, which is a leading manufacturer of plexiglass sheet, and provides machining services including the acrylic prototype. If you are looking for a reliable supplier, please contact us.

Need A Trustworthy Supplier Of Acrylic Product

Click on the button, you will find the Trustworthy Supplier Of Acrylic-based product and machining services.