Acrylic vs PETG

Introduction

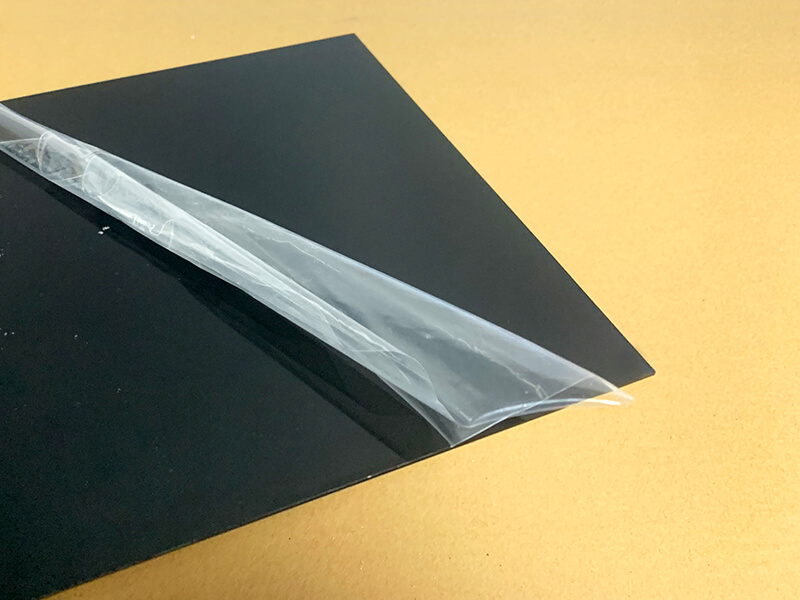

Acrylic, PETG (Polyester Terephthalate Glycol Modified), and polycarbonate are used for covers, machine guards, displays, glass, and other applications that need to be transparent and clear and have no colors. All of them can be found in sheet, tube, or rod form.

Each material has advantages and disadvantages that you should keep in mind before selecting them for an application.

Acrylic is manufactured using two processes: cell casting and extrusion. Acrylic sheets made by the extrusion process are the most common and inexpensive. However, the cell casting method is considerably more expensive due to its manufacturing process, requiring extensive time and labor.

On the other hand, PETG is much more durable and robust than acrylic. It also provides superb toughness, gloss, and chemical resistance, making it an excellent choice for machine guarding.

What Is Acrylic?

Acrylic material is more similar to glass, with higher clarity and light transmittance than glass. However, acrylic is more prone to subject breakage due to its rigid nature. Acrylic is a thermoplastic, generally a transparent homopolymer.

Acrylic sheets are widely used in many applications, such as casting resins, coatings, medical devices, mobile cases, and more. Moreover, they are a good choice for DIY projects as they are straightforward to shape and custom compared to standard glass. Another good thing about acrylic is that it allows less water permeation.

What Is PETG?

PETG is a good option for beginners as it is much easier to heat up and bend than acrylic. However, it is less clear than acrylic, has a much lower melting point, and is more prone to breakage and staining.

However, due to its lower melting point, PETG is easier to bend and shape. However, the main issue with PETG is that it is very prone to deformation as it has minimal temperature and pressure resistance.

Acrylic Vs Petg: Basic Differences

Acrylic and PETG are both popular choices for POP displays. However, both materials have advantages and disadvantages. For instance, acrylic is not as strong as PETG but is clearer and shinier, making it ideal for displays that don’t require physical interaction, like Aisle displays.

PETG is suitable for displays like cash registers or ATM booth monitors where customer interaction is a concern. But there are other aspects to consider before choosing any material; let’s look at them.

1. Color

Acrylic is available In different color standards, whereas PETG is generally colorless but can be colored depending on the cost and production volume.

2. Costs

PETG is an inexpensive material, but the cost mainly depends on the application of the material. On the other hand, like PETG, acrylic is also an affordable material primarily regulated by design factors. Example- thickness.

3. Production Issue

When it comes to acrylic, no genuine issue was seen regarding chemical elements, and the temperature is appropriately monitored. They are effortless to bond compared to PETG with more options. Meanwhile, producing PETG requires proper lasers, and it can form a yellowish color around the edges due to improper lasers. Moreover, they need adequate agents to bond.

4. Stability

Although acrylic is more prone to breakage than PETG, it offers excellent flexibility and exceptional heat and impact resistance. However, this feature allows the material to take more bending without breaking. It is a perfect choice for DIY projects. PETG is strong and does not break easily. It is an excellent choice for long-term use.

5. A Better Option For Pos

Acrylic is suitable for POS applications. PETG is strong but is less scratch-resistant than acrylic due to its soft surface nature. It also has a slight tint. On the other hand, acrylic is more resistant to scratches and has a shiny finish. In terms of clarity, acrylic beats PETG.

Acrylic VS PETG Tubing

Both materials offer similar tubing experiences and work in similar ways. However, there are some slight differences between them, which we should keep in mind before choosing any of them.

Acrylic Tubing

Advantages

Acrylic is the closest thing to glass used as an alternative. It provides superb clarity. Though acrylic is more prone to shattering than PETG, it has a higher melting point, making it more durable when your system heats up.

Acrylic is better in other ways, it also offers more stain and scratch resistance than PETG.

Additionally, it reflects more light, so your tube will look aesthetically blessed for longer. Acrylic tubing also allows less water permeation, so you often don’t have to top up your loop. However, one disadvantage of acrylic is that it takes longer to reach the melting point due to its high melting point, and the material is too brittle for essential tools.

PETG Tubing

Advantages

PETG is a great option for beginners, but many water-cooling enthusiasts avoid it. However, its lower melting point makes it easy to shape and bend and fix any mistakes.

It has the edge over acrylic in terms of using basic tools. In addition, due to its durability, it can handle any material and tooling quite well. But PETG tubing has less clarity than acrylic and is more prone to staining. For this reason, unlike acrylic, it is not ideal for most coolants.

Conclusion

Acrylic and PETG are both suitable materials for tubing. However, you should know some key differences when considering either. But before selecting any one of them, we advise you to consider your objectives first.

Need A Trustworthy Supplier Of Acrylic Product

Click on the button, you will find the Trustworthy Supplier Of Acrylic-based product and machining services.