glass vs acrylic

Introduction

There is always confusion between acrylic and glass; which one is better?

Acrylic sheets are a type of plastic with many advantages over standard glass, and they can be used as an alternative to glass in several ways. But you must know when to consider standard glass or when to opt for acrylic.

So, let’s compare acrylic and standard glass and take a closer look at the differences between each material.

What Is Acrylic?

Acrylic is a thermoplastic- specifically, Polymethyl methacrylate (PMMA). It’s a transparent homopolymer. It is widely used as an alternative to glass, but it also has other uses, such as coatings, casting resins, medical devices, mobile cases, and many more.

This material is comparatively more robust, durable, shatter-resistant, scratch-resistant, and eroded than standard glass. However, glass is more cost-efficient and easily recyclable than acrylic.

Depending on the manufacturing process, acrylic sheets can be more scratch-resistant than glass or extremely impact-resistant. Therefore, it is used comprehensively in a lot of applications.

For instance, eyeglass lenses are an everyday use of acrylic because they are more resistant to shatter and scratch. In addition, they produce less reflection compared to glass, reducing the amount of glare.

Plexiglass is another version of the acrylic sheet used as a generic term to relate different products manufactured under other names involving plexiglass. Several brands like Crylux, Lucite, and Perspex produce plexiglass acrylic products in modern days.

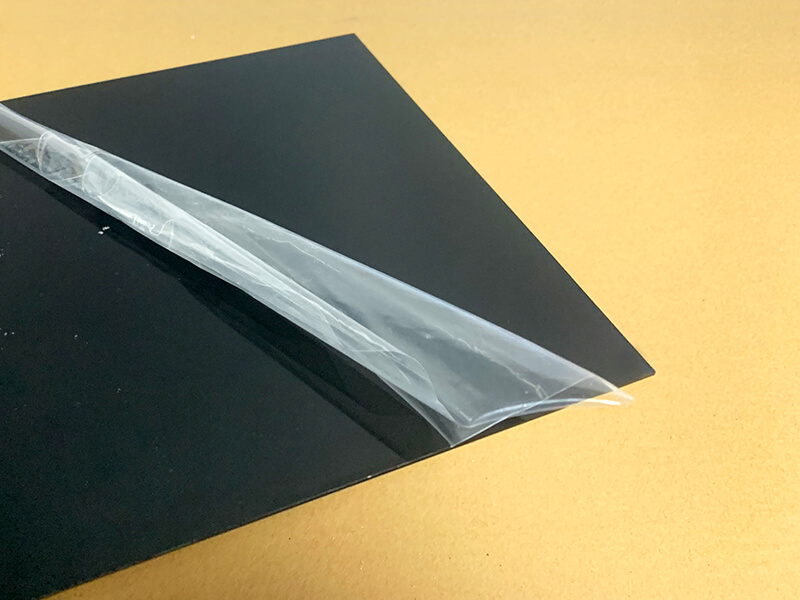

What acrylic can be found in the market

Acrylic can be made into different shapes, for example:

What Are the Core Differences Between Glass and Acrylic?

The difference between glass and an acrylic sheet is very narrow; actually, there are more similar qualities than differences, to be precise. The only difference we see is how both products are manufactured. But some key factors differ one from another. So let’s take a look at them.

1. Manufacturing Process

Acrylic is manufactured using two processes: cell casting and extrusion. The cell casting process includes a cell created by pouring unreacted acrylic between two panes of glass. After the reaction is completed and the acrylic has cured, the glass is separated from the acrylic sheet to inspect. This process tends to be more time-consuming, labor-intensive, and costly.

On the other hand, the extrusion process involves a method of extrusion, as the name says. The acrylic is continuously extruded until a sheet of acrylic is created.

The primary components used for making glass are sand, limestone, soda, and clarifying agents. Glass is made from a mixture of sand, lime, and soda melted at a very high temperature to form a new material.

In a word, glass is made out of liquid sand. Later a liquified glass is poured, pressed, and molded into different shapes. This process is known as the “press and blow process.”

2. Recycling and Cutting

Plexiglas are much easier to cut than regular standard glass, and they can be easily customized into different shapes and sizes to construct things such as tabletops. Although glass’s fragile nature makes it difficult to cut and shape, a simple mistake could lead to the subject breaking. Glass is straightforward to recycle as it needs only heat to recycle. On the other hand, Plexiglas is hard to recycle as it is made from petrochemicals.

3. Durability

Plexiglas is made out of thermoplastics, increasing its durability in the process, whereas glass is made from frozen liquid, making it more prone to breaking or shattering. But, standard glass is the clear winner when it comes to cleaning.

Glass doesn’t react to common cleaning products, but acrylic sheets can easily crack when touched with cleaning solvents. Moreover, improper cleaning methods can scratch the surface of Plexiglass panels. Standard glass is compatible with most cleaning solutions, and it is difficult to scratch and more impact-resistant.

4. Thermal Insulation

The thermal insulation of acrylic is much better than that of standard glass. In a word, the thermal conductivity of acrylic is lower than glass.

Apart from these slight differences, these products are very similar. The service of both materials mainly depends on their application.

When to Choose Acrylic?

Acrylic is a good option where weight plays a crucial role, such as in caravans, boat windows, aquariums, etc. Thanks to its low weight, acrylic could also be the perfect choice for DIY projects such as nameplates and side tables where material processing is essential.

Acrylic is far stronger and up to 15 times more impact-resistant than glass. As a result, it is widely used as an alternative to glass in areas where safety and security are primary concerns.

When to Choose Glass?

Glass is a common material used for applications that direct contact with sunlight and UV rays, such as house windows and automobile glass. However, when it comes to security and safety, if you place your window in a shade far from heat exposure, an acrylic sheet or polycarbonate sheet can be used as an alternative.

Glass is often used where safety is the primary concern and temperature is an issue.

Why Choose Acrylic Over Glass?

The differences between these materials seem very narrow, but you should consider some significant aspects before choosing one.

One of the most convincing benefits acrylics offer is that it is much tougher and lighter than glass. As a result, acrylic provides more versatility and flexibility in customization and DIY than glass.

As acrylic is built strong, it is obvious that it will be more durable and robust in most applications. Moreover, acrylic has a light transmittance of 92%, whereas glass admits up to 80-90% of light at best. As a result, acrylic sheets can resist impact up to 17 times more than glass.

When it comes to glazing applications, acrylic sheets have higher thermal insulation than glass, giving your structure a more aesthetic outlook. Furthermore, acrylic is a more cost-effective material than glass because it is lighter, making it cost-efficient during transport. On the other hand, glass is heavy and very prone to breakage.

Benefits of Acrylic

Benefits of Glass

Conclusion

Acrylic can replace glass in most daily use. But in very special uses, such as experimental apparatus, high-temperature glass, etc., acrylic can’t replace glass. If you want to discuss more differences between glass and acrylic with us, please send an email to [email protected].

Need A Trustworthy Supplier Of Acrylic Product

Click on the button, you will find the Trustworthy Supplier Of Acrylic-based product and machining services.