What is the acrylic material?

Know More About Acrylic

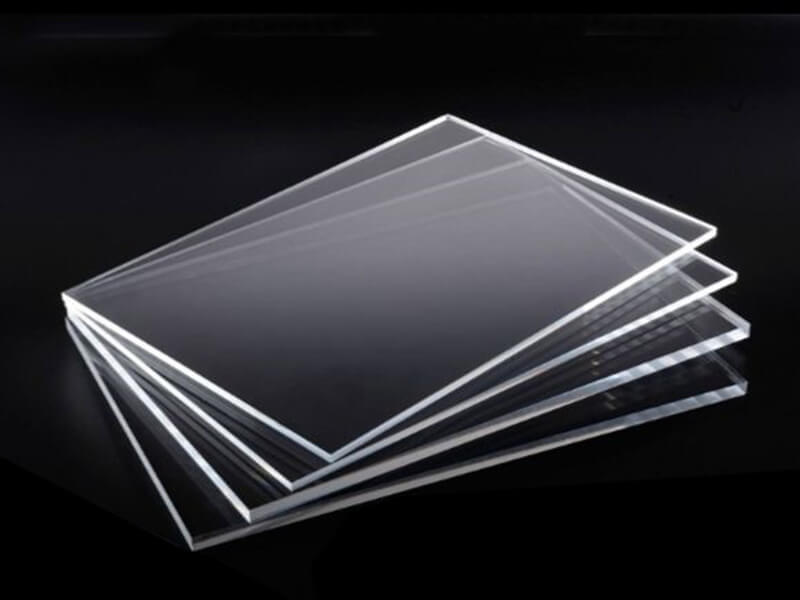

Acrylic includes monomers, plates, pellets, resins, and composite materials. Acrylic sheet is polymerized by MMA, namely PMMA. Plate plexiglass is a kind of plexiglass processed by a special process. It has the reputation of “Plastic Queen”. The research and development of acrylic have a history of more than one hundred years.

Whats is acrylic?

Acrylic, also known as PMMA or plexiglass, has a chemical name of polymethyl methacrylate. It is different from polycarbonate sheet, this article will tell you the difference between acrylic and polycarbonate.

It is an important plastic polymer material that was developed earlier. It has good transparency, chemical stability, weather resistance, easy dyeing, easy processing, and a beautiful appearance. It has a wide range of applications in the construction industry. Plexiglass products can generally be divided into cast plates, extruded plates, and molding compounds by PMMA Injection Molding Process.

Is acrylic plastic good?

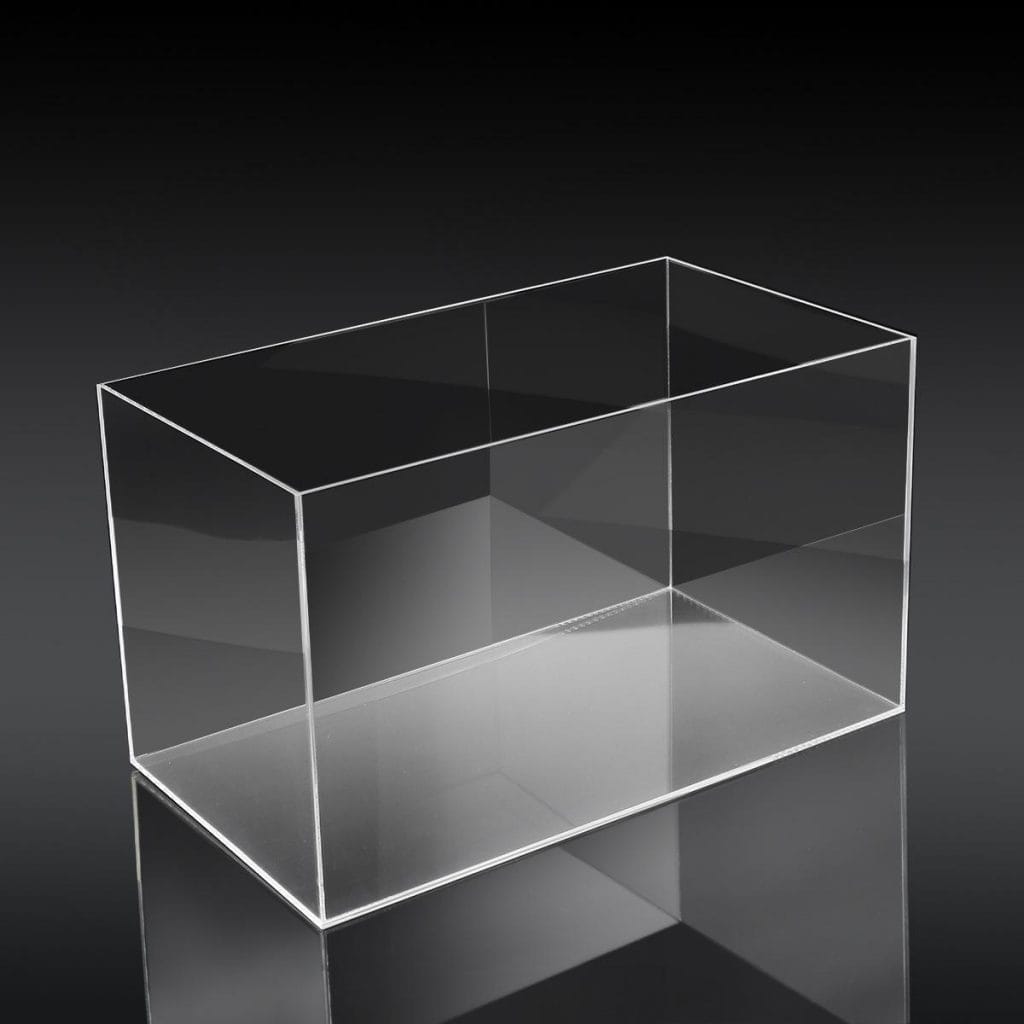

Acrylic plastic is one of the world’s oldest synthetic materials available. If you aren’t familiar with plastic, it’s a common material that is often referred to as Plexiglass. Popularly used in a variety of different applications across industries including displays, mirrors, picture frames, furniture, aquariums, DIY projects, and more—this synthetic polymer is a versatile material with distinct advantages.

Acrylic is

- Easy to Fabricate

- Easy to Shape

- Lighter than Glass

- Stronger than Glass

- Highly Transparent

- Easy to Clean

- Easy to Maintain

1、Unparalleled outdoor weather resistance, the panel is coated with high-concentration ultraviolet absorber, and the metal base is sprayed with imported car paint, which can maintain long-term weather resistance, no fading, and the service life is as long as 5-8 years.

2、The transparent plate is as clear and transparent as crystal, 200 times that of glass products, and there is almost no danger of breaking.

3、The surface has high gloss, smoothness, and flatness, the light transmittance is as high as 93%, the light transmittance is excellent, the light is soft, and the light is bright.

4、There are transparent, translucent, milky white, and other colors and various surface effects. It adopts a new type of polyester material, which is formed by thermal bending or flat edge, and the metal support has a built-in light source, which has great visual impact.

5、Excellent processing performance; thermoforming is easy to process and reasonable in cost when making signs and signs with outstanding visual effects. The craftsmanship is exquisite, the whole font has a mirror effect, the base has no wrinkles, no seams, and all the rivets are not exposed.

6、Green and environmental protection, waste materials can be completely recycled, and recycling is simple and easy. The light transmission performance is good, the light source products are reduced correspondingly, electricity is saved, and the use cost is reduced.

7、Excellent surface hardness and scratch resistance. The product has good protection for the built-in light source and prolongs the service life of the light source product.

8、Good chemical resistance, better than most other plastic materials.

9、It is easy to clean, maintain, and ensure that the appearance of signboards and lightboxes is as new all year round, rational design, rainproof and moisture-proof, open structure, easy maintenance.

What is acrylic used for?

Acrylic products include acrylic sheets, acrylic light boxes, signboards, acrylic bathtubs, etc., with a wide variety of products.

Commonly seen acrylic products are acrylic products assembled from raw materials such as acrylic pellets, plates, or resins through various processing methods, combined with various parts of different materials and functions. As for the commonly heard acrylic fiber, acrylic cotton, acrylic yarn, acrylic nylon, etc., it refers to man-made fibers made by the polymerization of acrylic acid and has nothing to do with acrylic products.

What are the characteristics of acrylic?

With crystal-like transparency, the light transmittance is above 92%, the light is soft, and the vision is clear. Acrylic colored with dyes has a good color development effect.

Acrylic sheet has excellent weather resistance, high surface hardness and surface gloss, and good high-temperature performance.

Acrylic sheet has good processing performance, which can be processed by thermoforming or mechanical processing.

Transparent acrylic sheet has a light transmittance comparable to glass, but the density is only half that of glass. In addition, it is not as fragile as glass, and even if it is broken, it will not form sharp fragments like glass.

The abrasion resistance of acrylic sheet is close to that of aluminum, with good stability and corrosion resistance to many chemicals.

Acrylic sheet has good printability and sprayability, and the use of appropriate printing and spraying processes can give acrylic products an ideal surface decoration effect.

Flammability: It is not spontaneously combustible but is flammable, and does not have self-extinguishing property.

Advantages and disadvantages of acrylic

Advantage

Acrylic is the best new material for sanitary ware after ceramics. Compared with traditional ceramic materials, besides the unparalleled high brightness, acrylic has the following advantages:

good toughness, not easy to break;

strong repairability, as long as the soft foam is dipped in toothpaste, the sanitary ware can be wiped new;

soft texture, in winter there is no icy feeling;

The colors are bright, which can satisfy the individual pursuit of different tastes.

Basins, bathtubs, and toilets made of acrylic are not only exquisite in style, durable, but also environmentally friendly. The radiation level is almost the same as that of the human body’s own bones. Acrylic sanitary ware first appeared in the United States and has accounted for more than 70% of the entire international market.

Disadvantage

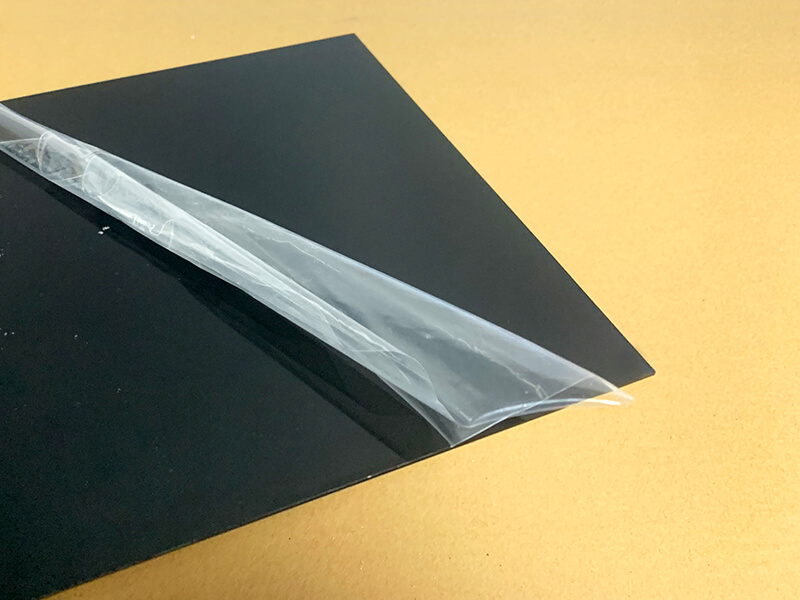

Due to the difficulty and high cost of acrylic production, there are many low-quality and inexpensive substitutes on the market. These substitutes are also called “acrylic”, in fact, they are ordinary organic boards or composite boards (also known as sandwich boards). The ordinary organic board is cast with ordinary plexiglass cracking material and pigment. The surface hardness is low, easy to fade, and the polishing effect is poor after sanding with fine sand. The composite board has only a very thin layer of acrylic on the surface and ABS plastic in the middle. It is easy to delamination due to thermal expansion and contraction during use. As for the way to distinguish true and false acrylic, you can refer to our blog to read.

Conclusion

In this blog, we give you a brief introduction to acrylic. As for other types of acrylic products, you can find them in more of our blog content.

UVACRYLIC is a leading China manufacturer of acrylic. Meanwhile, we provide custom acrylic-based products to global clients. If you have any special questions, you can also send us an email. We will answer for you.

Need A Trustworthy Supplier Of Acrylic Product

Click on the button, you will find the Trustworthy Supplier Of Acrylic-based product and machining services.