Why can acrylic replace the ordinary glass?

Know More About Acrylic

Glass is the first thing we come into contact with. In our opinion, transparent products are generally made of glass. We never thought that one day glass will be eliminated by a plexiglass sheet. Maybe acrylic products are constantly improved based on the disadvantages of glass to replace glass products. What is the leap of acrylic products?

The difference between acrylic and glass

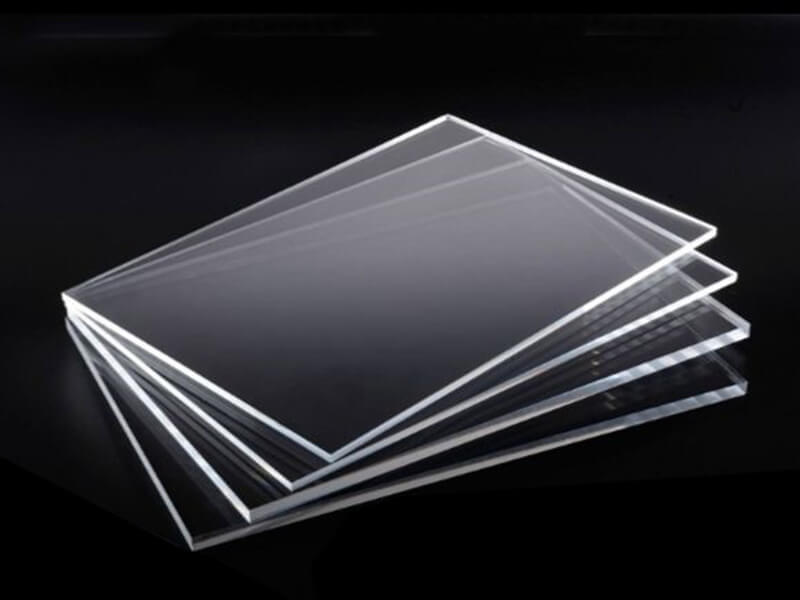

Acrylic, like glass, can be made into plates and other materials and has good light transmittance. If viewed from the naked eye, the two seem to be the same. At the same time, we can also see the two figures in daily furniture, such as fish tanks and other furniture, often can not distinguish between acrylic and glass, and this blog will tell the difference between acrylic and glass. Acrylic = glass?

Difference in material

What are the differences between acrylic and glass? First, let’s take a look at the material difference between the two. Acrylic is usually called PMMA, and its chemical name is polymethyl methacrylate, which is essentially the same as plexiglass. In fact, acrylic is a kind of thermoplastic decoration material style, which is a kind of high molecular polymer extracted from deep-sea petroleum. Many properties of acrylic are similar to those of plexiglass or plastic, but it has stronger stability and higher quality.

Glass is a silicate-type transparent solid substance fired from a large number of materials. The chemical composition of glass is generally Na2O·CaO·6SiO2, and the main component is silicon dioxide. Therefore, glass is different from plexiglass, which is the same high molecular polymer as acrylic, that is, plastic. In addition, adding some metal oxides or salt chemical substances to the ingredients of ordinary glass, that is, transparent glass becomes colored glass, such as a complete picture of colored glass cups, etc. At the same time, tempered glass can also be fired in some ways.

the difference in characteristics

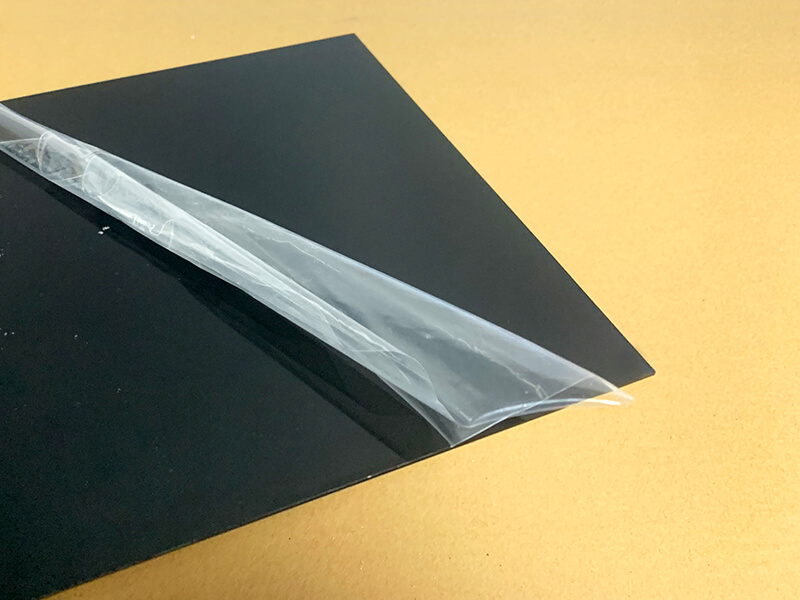

Let’s take a look at the difference between the characteristics of the two. Acrylic has high transparency, good chemical stability, and easy dyeing process, and a beautiful appearance. In terms of light transmittance, acrylic and glass have the same light transmission performance, but the density of acrylic is only the same as that of glass with the same light transmittance. It can be seen that the material of acrylic is very light, like acrylic ceiling lamp shades. Moreover, acrylic is resistant to falling and not fragile, and its hardness and strength are very good. In addition, acrylic is dyed with external fuel to make acrylic products of different colors.

The light transmittance of glass is the same as that of acrylic material, but it is easy to break. At the same time, the tip is very easy to hurt people. Generally, it will be processed around when making furniture such as glass coffee table styles. The compressive performance of glass is better, and the home crafts made by firing are more beautiful. In addition, glass is originally colorless and transparent. If it is necessary to make colored glass, it is necessary to add chemical substances to its own firing components to change its chemical properties, thereby performing “dying”.

the difference in function

Both acrylic and glass have a wide range of uses. For example, it is made into handicrafts, etc., or building materials. However, acrylic, a home improvement building material, is less breakable than glass, so it can be more used in outdoor places, such as billboards.

Acrylic = glass? All of the above can show that acrylic is not equal to glass. Whether it is material, characteristics, or function, we cannot confuse acrylic with glass. Acrylic is similar to plexiglass, and plexiglass is essentially plastic, not glass, and needs to be treated differently.

why acrylic products replace the glass

Let me explain to you the main reasons why acrylic products replace the glass.

1. High light transmittance

Acrylic has a very good light transmittance, with a light transmittance of more than 92%, while ordinary glass has a light transmittance of 85%. Therefore, dyed and colored acrylic craft products are crystal clear and very beautiful under sunlight!

2. Outstanding insulation effect

Acrylic has a very good insulation effect, which is expected in many electronic products, such as tablet computers, mobile phones, computers, audio, televisions, and other products used in some very small component insulators. If you use electronic products in repairing, pay attention to it, you can see it.

3. Strong weather resistance

Acrylic is very resistant to weather. It will not turn yellow or become broken due to exposure to the sun or freezing, making it very convenient for you to clean.

Everyone usually pays attention to products such as lightboxes, billboards, and roadside lamp covers on the road. Many of them are acrylic materials, regardless of wind, rain, snow, sun, lightboxes, and advertisements made of acrylic. Brand and lampshades have a very long service life because of the stability and lightness of the acrylic material. Think about it if such a tall lightbox is made of ordinary glass, and people walk down every day, if it falls…

4. Environmentally friendly

Acrylic is very environmentally friendly and can be used repeatedly. You may usually encounter that the glass is broken as soon as it is dropped, just take the broom and sweep it to the trash can. Some products made of ordinary glass are heavy and inconvenient to carry when you move. It is a pity to lose it. You can’t sell it at a good price if you sell it. But if you have products made of acrylic materials at home, don’t be so prodigal. The recycling of waste products of this kind of material is very expensive! Whoever collects waste products knows.

5. Strong plasticity

Acrylic has a very high freedom of shaping, and can be processed at will to become the type you want:

Because acrylic material is lighter than ordinary glass, and the cutting technology is not complicated, acrylic products can basically meet the needs of various industries for product customization, such as cosmetic display stands, photo frames, watch stands, or large-scale. The size, shape, height, and thickness of aircraft windows, fighter window covers, tank viewing angle windows, etc. can be made according to customer needs.

6. Strong impact resistance

Acrylic is more than 20 times more resistant than ordinary glass. This is true and tested abroad. When a certain thickness of acrylic material is placed in front of the test protector, a standard American M16 assault rifle is used for continuous shooting. It can’t penetrate and damage the target in front of acrylic material, so this is why acrylic is widely used as a bulletproof material in some foreign leaders’ special vehicles.

7. Strong corrosion resistance

Acrylic has a very strong anti-corrosion ability: this is no exaggeration to tell everyone that you can directly apply strong sulfuric acid to the acrylic material and there is no problem at all.

Conclusion

Based on the above 7 advantages, it is enough to replace the glass. This is also the reason why acrylic products have jumped up. Of course, this is only part of the advantages of acrylic products, otherwise, acrylic products will not be applied to various fields.

UVACRYLIC is a leading manufacturer of acrylic sheets in China, meantime, provides custom acrylic. If you have any questions about acrylic products, you can send us an email and we will be happy to answer you.

UVPLASTIC is the parent company, which is a leading manufacturer of polycarbonate in China and provides machining polycarbonate service. We manufacture great products base on polycarbonate, such as bubble tent, office chair mat, riot shield, etc.

Need A Trustworthy Supplier Of Acrylic Product

Click on the button, you will find the Trustworthy Supplier Of Acrylic-based product and machining services.