Acrylic Vs Polycarbonate Light Diffuser

The LED diffuser is an optical device with light-scattering properties mounted in the direction of the light source. It smoothes the illumination and minimizes the sharpness of shadows. Diffusers ensure uniform illumination from light-emitting diodes (LEDs) and are thus an essential part of the overall lighting system.

The global light diffusion materials market can be divided into polycarbonate (PC), acrylic, polypropylene, and other sheets based on product. Acrylic and polycarbonate plastics are often recommended for various applications where the material’s size, weight, and strength must be considered. While contrasting acrylic and polycarbonate lighting lenses, it’s necessary to consider the user’s strategic objectives.

But which one is the best? Here in this article, we will dig into which is superior and why.

What Is An Acrylic Diffuser?

Acrylic diffusers produce a soft lightning effect by regulating the brightness of harsh lighting. They can also help save energy by offering more even lighting, reducing the need for additional fixtures. Besides, they protect lighting fixtures from dust as well.

Bulk polymerization is the process by which acrylic plastic polymers are formed. Batch cell or continuous system processing is used to form the acrylic, depending on the thickness and shape required.

What Is A Polycarbonate Diffuser?

Polycarbonate Light Diffusers are made of polycarbonate plastic with thicknesses ranging from 0.06mm to 5mm. They are the right material for LED lights, DIY lights, Automotive Interior lights, HUDs, office lamps, kitchen lights, and fluorescent lights.

Bisphenol A (BPA) and Phosgene are used to make it. Polycarbonate can be made in a variety of ways, including by free radical polymerization. Polycarbonate has the benefit of being a thermoplastic, which means it can be molded while still hot. It can not quickly melt or be formed after it has cooled.

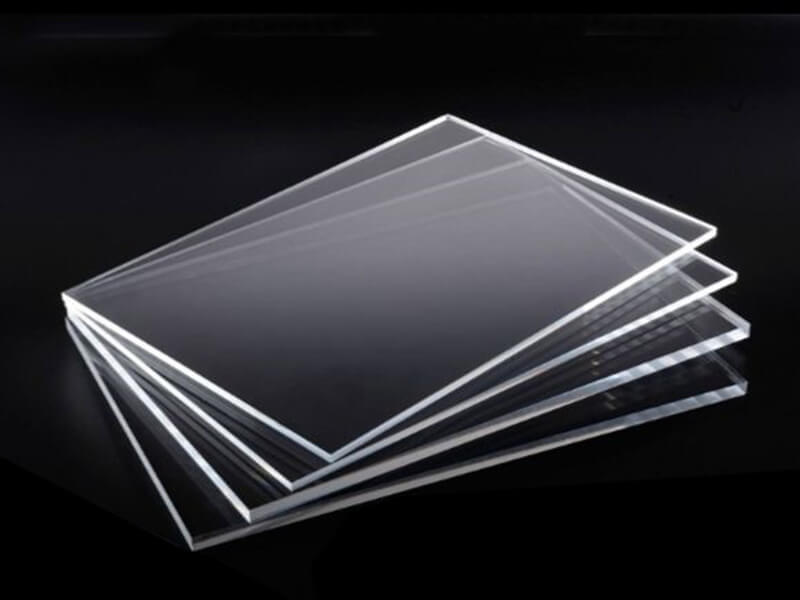

Acrylic Light Diffuser VS. polycarbonate Light Diffuser

Various LED manufacturers consider acrylic and polycarbonate (PC) to be suitable light diffusion materials. Because of their low absorption coefficient and design freedom, these two transparent and designable plastics are slowly replacing glass in LED applications.

Here to differentiate these two light diffusers, we will focus on the qualities of both diffusion materials.

Acrylic Light Diffuser

Polycarbonate Light Diffuser

Is Polycarbonate or Acrylic Stronger?

Polycarbonate is 250 times more impact-resistant than acrylic, which is just 17 times as strong as glass. Polycarbonate manages material tension more effectively and has higher impact resistance than acrylic because it is less rigid. You can purchase it with various levels of versatility.

Acrylic is more prone to chipping and is slightly more flammable than Polycarbonate, burning slowly and not suitable for use in areas where flames are present or possibly.

So Polycarbonate is much stronger. Therefore, most manufacturers of LED floodlights use them for diffuser panels.

What Material Is Best For Diffusing Light?

Obviously, the answer is acrylic. Because as compared to polycarbonate, acrylic has better optical properties. It has a strong light transmission, diffuses LED hot spots, and is simple to put together. Acrylic sheet is used in various lighting applications, including fixtures for commercial lighting, displays at the point of sale, and signs with backlighting. Most importantly, manufacturers like you prefer acrylic due to its optical properties at affordable pricing.

Which One Should You Choose?

A variety of materials can create light diffusers, but acrylic plastic is one of the best. Consider the following cases first:

For both cases, Acrylic light diffusers are the plastic material with the best light transmission capabilities. Besides, these diffusers soften the light emitted by your LED fixtures. So, there is no light-diffusing material that provides a cost-effective and straightforward solution like Acrylic.

Why Do We Recommend Acrylic For Your Light Diffuser?

There are numerous logical reasons why we recommend Acrylic diffusers for your light diffuser. Just dive into the following advantages:

Acrylic Is Cheap

Acrylic is less expensive than polycarbonate. Polycarbonate is typically 30-40% more costly than Acrylic, depending on the finished product and length.

Acrylic Is Durable

Acrylic plastic diffusers are mechanically robust, and well-made acrylic diffusers can survive several years of use. They are more resistant to cracking and can withstand more physical violence than polycarbonate and glass diffusers.

Acrylic Transmits More Light

All light diffusers reduce the amount of useful light emitted by an LED fixture. Polycarbonate or frosted glass diffusers will dramatically dim your lights. Acrylic plastic has a special structure that allows it to disperse light efficiently. It also reduces usable light levels to a minimum.

Acrylic Is Scratch Resistant

Acrylic plastic diffusers are often more scratch-resistant than other materials. Moreover, they will not discolor when exposed to direct sunlight, as polycarbonate plastic diffusers often do.

Acrylic Is Versatile

Acrylic plastic is a very flexible option if you need to make light diffusers with printed designs. It is also perfect to create a unique diffuser design for a hotel lobby or corporate conference center. You can easily create exquisite and stunning custom diffuser designs that will give your commercial space some serious visual flair.

Final Word

Apart from our recommendation, several factors should be considered when choosing a plastic material for the light-diffusing application: the type of light source, the impact potential, flammability standards, outdoor exposure, budget, and temperature range. If you need more information about acrylic light diffusers and polycarbonate light diffusers, please send Email to [email protected].

Need A Trustworthy Supplier Of Acrylic Product

Click on the button, you will find the Trustworthy Supplier Of Acrylic-based product and machining services.