Can Infrared Pass

Through Acrylic? Get the Right Info Here!

Can infrared pass through acrylic? Read this effective guide and find out how acrylic handles infrared (IR) light and blocks other wavelengths.

Acrylic is the most popular synthetic material that is widely known for its variety of purposes and benefits. But can infrared light pass through acrylic? The answer is yes!

Acrylic is formulated for special projects that require ultraviolet (UV), visible light blockage, and fluent transmission of IR.

With an infrared band from 700 to 1400 nanometers, a 3 mm acrylic sheet allows about 90% of infrared light. However, as the sheet gets thicker, the transition rate reduces, and at 2200 nanometers, it completely blocks the light.

Read on to learn more about the IR transmission capabilities of this specialized plastic.

Does Infrared Light Pass Through an Acrylic Sheet?

Acrylic sheets have all those unique properties that can easily pass through the IR rays, especially in the 700–1400 nanometer range. It even has the capability to block harmful UV rays and other visible light from entering the applications.

The physical properties of the material are almost similar to any standard extruded sheet, and you can even use the same fabrication methods to work with them. What sets this product apart is its unique ability to transmit IR light while blocking the UV light.

However, the overall transmission rate of the acrylic is defined by its thickness. As the thickness of the acrylic sheet increases, you will find that the rate at which it transmits infrared radiation decreases slightly.

Typically, sheets stop the IR transmission at 2200 nanometers (as you can see in the below graph).

How Does Acrylic Interact With Infrared Light?

Infrared acrylic sheets are made with unique chemical and physical properties that make the near-infrared (NIR) light transparent. It mainly transmits infrared light due to molecular structure and the way it interacts with infrared radiation.

That means the molecular structure of these sheets doesn’t absorb the infrared radiation in the near-infrared spectrum and allows it to easily pass through.

But as mentioned earlier, how much passes through acrylic sheets depends on how thick the sheets are. The molecular structure of the thicker acrylic sheets absorbs more infrared radiation and reduces the transmission.

Even some manufacturers add certain additives that affect its infrared transmission properties.

Key Properties of Acrylic That Can Transmit Infrared

Here are some notable physical properties that make it possible to transmit the IR across various industrial applications:

| Property | Description |

| Higher transmittance | Acrylic transmits IR light with wavelengths less than 2800 nm and blocks IR light with wavelengths less than 25,000nm. |

| Lower melting point | Most of the acrylic has a low melting point that is approx. 130–140°C (265–285°F). This makes it ideal to use in applications where it might be exposed to significant heat. Note: High temperatures can cause expansion, contraction, or deformation and IR transmission. |

| Durability | Acrylic is highly durable and resistant to environmental factors. This helps it to maintain its IR transmission properties over time, even in such harsh conditions. |

| Mechanical Strength | Acrylic is much stronger than regular glass because of its long-chain polymer structure. It has a molecular mass of about 2 million, which makes it 7–18 times more stretchy and impact-resistant. This ensures that acrylic can withstand physical stress and maintain consistent IR transmission. |

Common Acrylic Plastics That Are Relatively IR Transparent

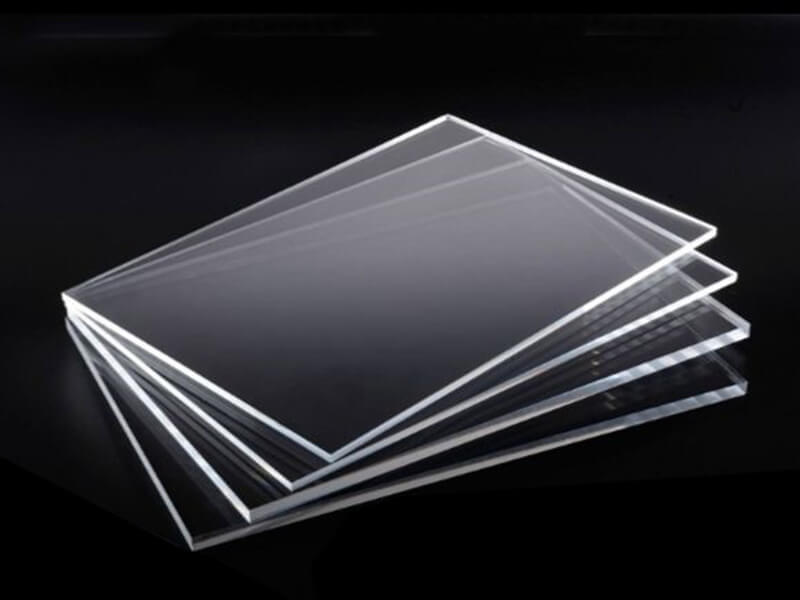

There are various types of acrylic sheets available on the market that can transmit IR light under specific conditions. Here are some common types of infrared-transmitting acrylic you should know about:

UVACRYLIC® Extruded (UVAC-IRT)

UVACRYLIC® UVAC-IRT is a famous Infrared Transmitting Acrylic, it offers different grades, it can transmit infrared rays while blocking ultraviolet (UV) and visible light. Meantime, you can get the machining services. UVACRYLIC is a China brand, product quality and service are good. You will find it commonly used in displays, glazing, and other applications where high transparency and durability are crucial.

ACRYLITE® Cast (GP)

ACRYLITE® GP is in the range of cell-cast acrylic sheets that are made to exact the standards. The sheets are highly known for their high optical clarity and strength. Beyond all that, it offers high infrared transparency, through which you will get up to 90% IR transmission at 3 mm thickness.

ACRYLITE® Extruded (FF)

This is another most common acrylic sheet that is made through an extrusion process. However, similar to the cast version, this colorless extruded FF sheet has a substantial infrared transmission capability that makes it ideal to use for light piping applications, such as engraved signs, inspection lights, instrument dials, and other similar items.

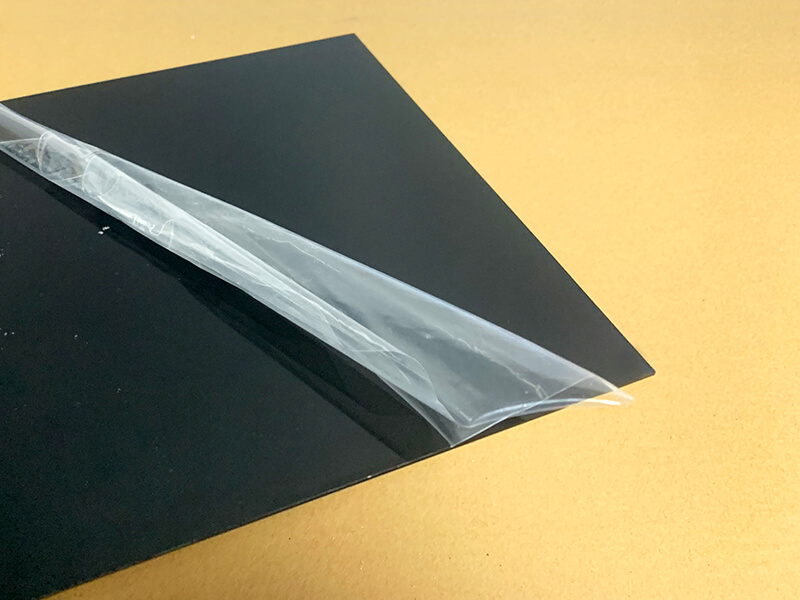

ACRYLITE® IR Acrylic 1146

Acrylic 1146 has the same properties as infrared acrylic, which makes it possible to transmit IR but absorb visible light. This generally comes in black in color. This is the ideal color for use in applications like security cameras or infrared transmitters and receivers where you need to conceal the IR.

Plexiglas® IR Acrylic 3143

Plexiglas G sheet color 3143 is also in the range of the acrylic sheeter that is designed to block visible light and transmit IR light. You will find these sheets in common applications like remote control devices, laser lenses, and heat sensors.

Applications of Acrylic in Infrared Technologies

As with the advancement of technology, acrylic, particularly infrared-transmitting acrylics, is significantly used in various infrared technologies. Here are some common applications you can note down:

Remote Controls and Sensor

Due to its high ability to allow IR light to pass through, acrylic is used as a protective cover in remote controls and sensors. The shield is more likely to work against the UV and other visible light to interfere with the functions and allow IR signals to pass through.

Surveillance Cameras

Infrared-transmitting acrylic is found in various security applications like CCD cameras, where IR transmission is necessary for night vision and in low-light conditions.

Heating elements

Most acrylics have a thermal conductivity of 0.19–0.2 W/(m°C), which makes them perfect to use in applications where heat retention is ultimately desired. For instance, the physical properties of the sheet effectively distribute heat evenly without any significant heat loss and enhance energy efficiency.

Medical equipment

Various medical applications, such as medical imaging equipment, therapeutic devices, and the laboratory industry, successfully incorporate acrylic sheets to allow IR transition and protect functions against UV exposure.

Photography

You will find acrylic plastic widely used in various camera lenses. For instance, the transmitted IR light helps to capture clear and sharp IR images.

Major Factors That Can Affect Infrared Transmission Through Acrylic

Now that in this stage of our discussion, let’s highlight some of the major factors that can affect the IR transmission ability of infrared acrylic. Have a look:

Pigment Additives

Pigments can influence infrared (IR) transmission through acrylic. Points to note that cool pigments, which include both organic and inorganic types, tend to have weak absorption and strong backscattering in the near-infrared (NIR) spectrum. This mainly reduces the amount of heat while reflecting more NIR light.

Temperature

Along with the additives, the temperature also has a high impact on the IR transmission of any infrared material. Material exposed to high temperatures affects the optical properties of acrylic, causing expansion or warping and impacting the performance.

Humidity

High exposure to humidity can lead to moisture absorption as well as expansion or contraction in acrylic. This distortion can alter the path of IR light passing through the sheet.

Atmospheric Contamination

Dust, dirt, and other contaminants on the surface of acrylic can obstruct IR light and reduce transmission efficiency.

Surface Coatings

If you are applying any additional coatings to acrylic. It can affect its IR transmission. Here the coating can reflect or absorb IR light, which may change IR radiation transmission capability. However, AR (Anti Reflection) Coating can increase the infrared transmittence.

In Closing

Along with its various uses, acrylic is a versatile plastic that can even transmit IR in a specific spectrum. This is the unique benefit of this material that makes our daily lives far easier. You will be seeing our industry upgrade with this demanding sheet day by day.

Need A Trustworthy Supplier Of Acrylic Product

Click on the button, you will find the Trustworthy Supplier Of Acrylic-based product and machining services.