Infrared Transmitting Acrylic: How to Choose Wisely

Are you concerned about the perfect acrylic infrared transmitting sheet for your project? Find solutions here. Learn the key factors to select the top-notch sheet.

A perfect infrared transmitting acrylic with the right specifications is more likely a game-changer for your project’s success! No matter if you are using it in high-tech remote control and any precision sensors, the right sheet is enough to make an unbelievable difference. But the thing is not like just picking any acrylic sheet and starting to apply it to your devices.

Remember, a wrong sheet can cause poor performance and harm your application. In this guide, we will highlight all the major factors that make an acrylic sheet stand out. This will help you select a sheet that will boost your project’s efficiency. Let’s move on!

What is an Infrared Transmitting Acrylic and How It Works?

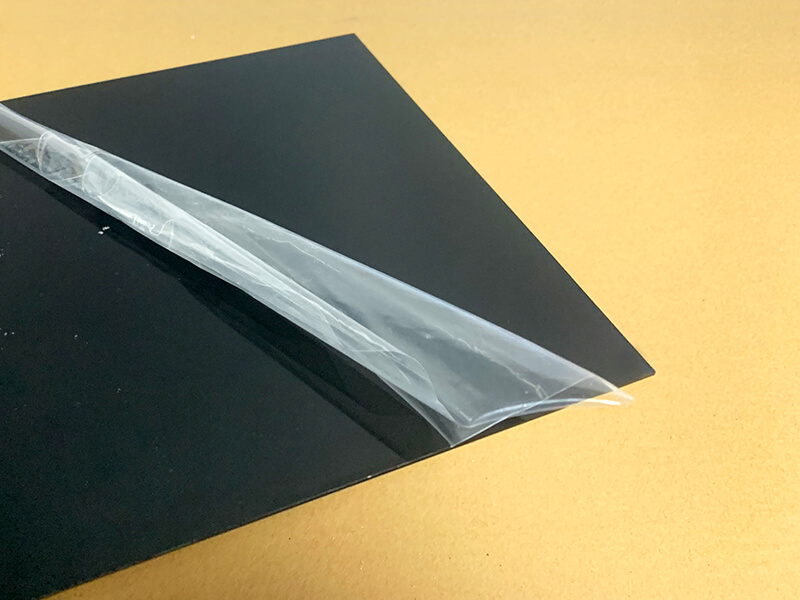

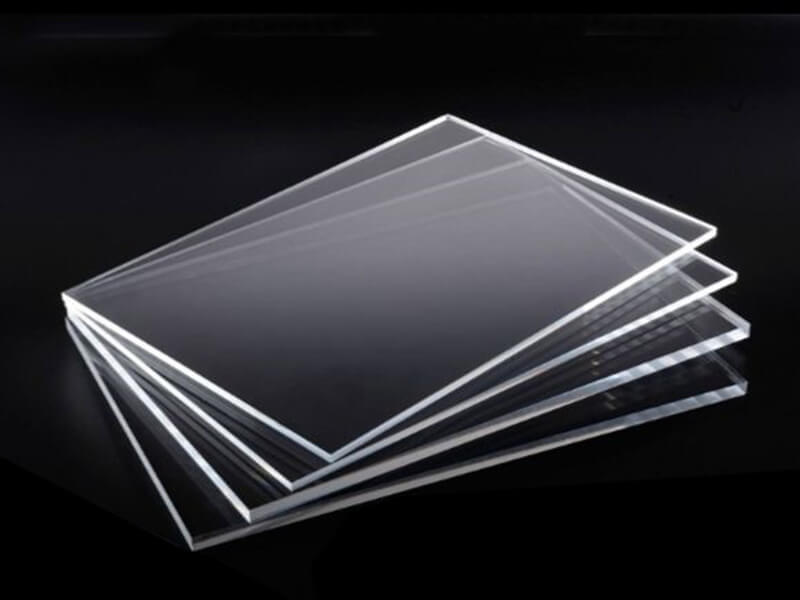

Infrared-transmitting acrylic is in the range of high-grade acrylic plastic that is designed to allow infrared light to pass through while blocking other wavelengths. Though the physical properties of the sheet are almost similar to the traditional acrylic sheeting, the specialty lies in its unique properties to transmit IR.

The outstanding performance of this plastic makes it ideal for various applications. Typically, you will find the acrylic black in appearance, which has the capability to absorb visible light and harmful UV rays. It is highly resistant to environmental factors and mechanical stress.

8 Key Factors for Choosing the Right Acrylic Infrared Transmitting Sheet

Suppose you want to ensure optimal performance for your specific application, whether in sensors, remote controls, or security systems. In that case, it is important to select an acrylic infrared transmitting sheet. For your convenience, here we’ve listed 8 major factors from expert suggestions you can consider in this instance.

1. Wavelength Range

This is the key to choosing the absolute acrylic infrared transmitting sheet for your applications. Different infrared applications require specific wavelength ranges to function correctly. All you need to do is ensure that the sheet matches your project’s needs.

Always check the specifications provided by the manufacturer. Typically up to 3 mm thick and in the penetrating infrared band from 700 to 1400 nanometers, an acrylic sheet allows approximately 90% of infrared radiation.

This indicates the high transparency to infrared light of the acrylic within this specific range.

2. Thickness

This is the must-check, and it will highlight how IR transparency works in your applications through the infrared transmitting material. As with increasing the thickness, the ability to transmit light decreases slightly.

Specifically, in the wavelength range of 1400 to 2200 nanometers, you will find the sheet transmits less and less radiation as the wavelength increases. Besides, when the wavelength reaches 2200 nanometers, the sheets transmit almost no radiation.

That means the material becomes nearly opaque to radiation at this longer wavelength. The right thickness not only impacts the IR performance but also determines the sheet’s strength, flexibility, and optical performance. So, don’t miss checking and ensuring this major factor is correct!

3. Optical Properties

The optical designs of the infrared material are another major factor to consider while selecting the correct infrared acrylic sheet. This includes transparency, refractive index, and light transmission efficiency.

For instance, start by checking the refractive index, which mainly tells you the material’s ability to control and manipulate light.

High light transmission efficiency ensures optimal performance in applications like sensors or cameras. Then, consider dispersion, which highlights how different wavelengths of light are refracted by the material.

If your application involves precise optical tasks, like imaging or spectroscopy, high dispersion can cause chromatic aberrations and rescue the image quality. Check and ensure all these requirements are against your project’s specifications.

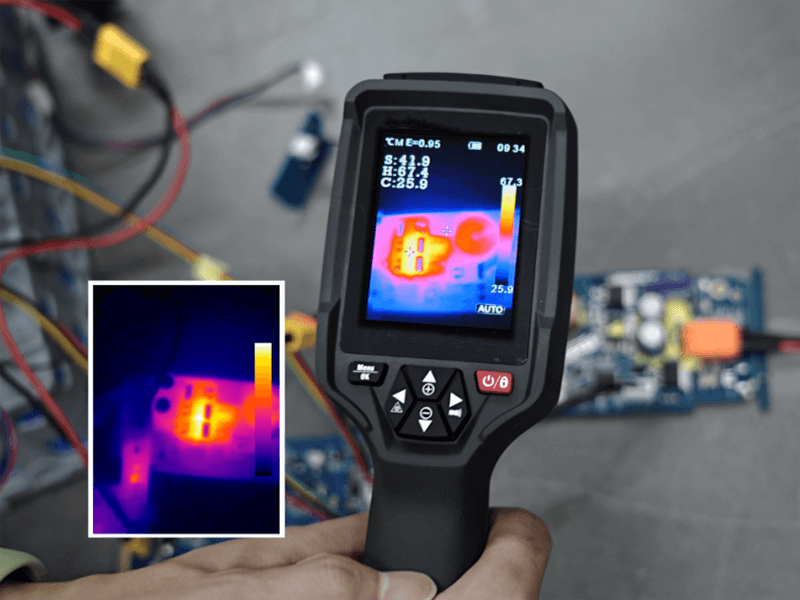

4. Thermal Properties

Along with other factors, consider thermal properties when choosing an acrylic infrared transmitting sheet. Though IR wavelengths don’t transport heat directly, they excite molecules, which causes them to vibrate and rotate.

For this, you need to understand the material’s heat resistance and thermal expansion. Take note that high heat transparency is important for applications involving high temperatures that ensure the sheet won’t deform or degrade.

Also measures how well a material transmits heat. Acrylic sheets with lower thermal conductivity absorb more energy and heat up more.

5. Mechanical Properties

Mechanical properties are crucial when you are selecting an acrylic infrared transmitting sheet. This includes tensile strength, impact resistance, and flexibility. For instance, high tensile strength ensures the sheet can withstand stretching and pulling forces. Besides, robust impact resistance is a must for the durability of the sheet.

Flexibility allows your sheet to bend without breaking for various applications. All you need to do is cross-check these specific requirements based on your project’s demands. This is crucial, as it will ensure the longevity and reliability of your application through using the acrylic sheet.

If you need higher impact resistance, you can choose infrared transmitting polycarbonate; it offers similar infrared transmittance but higher strength.

6. Durability

Durability is a key factor when you are selecting a high-performance acrylic infrared transmitting sheet to get long-term benefits. It is obvious that you want a material that can withstand wear and tear, environmental stress, and daily use.

For instance, check for resistance of your sheet to scratches, chemical properties, and UV radiation. You can review the manufacturer’s durability ratings and customer reviews to get real-world performance insight for your specific acrylic sheet.

Remember, a durable sheet will ensure long-term performance without frequent replacements. This is mainly important if you are looking for acrylic to use in outdoor or industrial applications.

7. Cost

As with ensuring high performance through durability, IR transparency, and optical properties, it is also important to ensure that you’re within your budget. Higher cost often means better quality, but proper balancing is the key.

All you need to consider is the long-term value of the material instead of initial pricing. Cheaper options can help you save money, but you may need more important requirements for your application. The suggestion is to find the right material at the best value for your investment.

8. Reputable Supplier

If you still need clarification about choosing the perfect infrared transmitting sheet for your specific project, this is the time to head to a professional one. A trusted supplier will guide you to high-quality materials and accurate specifications to apply to your applications.

Besides, by purchasing the sheet from reputable suppliers, you will have reliable customer service as well.

Anyway, the easiest way to research such trustworthy suppliers is by reading reviews and checking ratings from the customers. Besides, you can seek recommendations from industry professionals. Look for certifications and industry standards and compliance to guarantee the quality of the material.

In Closing

Here’s all about choosing the suitable acrylic infrared transmitting material. Whether you’re using it for high-tech devices or medical applications, selecting the right sheet is crucial to ensuring optimal performance. We hope that our article will be enough to guide you to the right information.

If you’re still confused about which sheet is best for your needs, consider consulting with a supplier or expert to get the right suggestions.

Need A Trustworthy Supplier Of Acrylic Product

Click on the button, you will find the Trustworthy Supplier Of Acrylic-based product and machining services.