Common Uses for Plastic Channels

Plastic channels are used in various applications, starting with machine rail guides or protectors for sensitive parts. They are also used for price tag moldings and decorative edge trims.

What do channels do? For water flow or industrial purposes, the channel can hold, guard, seal, and direct the liquid flow. Among different types and variations, the common plastic channel types include J-channel, H-channel, and U-channel.

However, more complex channel profiles are often extruded for applications, such as window insulation, which needs multiple internal heats and sound insulation gaps. Out in the market, there are a variety of materials for manufacturing plastic channels. But you need to determine which material suits your cause, let’s find out how.

Which Material Is Best for Plastic Channels?

Polycarbonate

People with high impact resistance generally prefer polycarbonate as the right material for plastic channels. This is because it provides a smooth surface finish and a high-gloss surface. However, if you want long-term service, polycarbonate plastic might not be appropriate. It can be made into polycarbonate rods.

If you need high-impact resistance, colorability, excellent smoothness, and long-term durability, acrylic plastics are the suitable material for you. On the other hand, polycarbonate might be impact-resistant, but they are not as durable as acrylic.

PVC

Depending on your specific requirement, this material is available in both rigid and flexible forms. In addition, they are available in clear and opaque colors depending on your purpose and can be cut to any size.

The advantage of using a flexible grade is that it can be curved and used. Although rigid PVC provides excellent impact resistance, it can be produced in the colors needed.

However, long-term applications require durability, which is available only in acrylic channels. PVC might deteriorate after a certain period, but acrylic keeps its state for ages.

Polyethylene (PE) and Polypropylene (PP)

If you do not require a high level of UV or impact resistance, you can opt for Polyethylene or Polypropylene. These materials are economical. PE is typically more flexible than PP in most cases. Typical applications for PP and PE are bag closure clips, pool liner clips, wire covers, and edge trims, etc.

Acrylonitrile Butadiene Styrene (ABS)

ABS profiles provide high-impact resistance with good colorability and smooth surface quality. They are primarily suitable for indoor applications. However, these profiles do not last long as they are durable enough to be used for indoor purposes only.

Acrylic plastic channels are the best choice when you want optimum durability, long-life service, and affordable material.

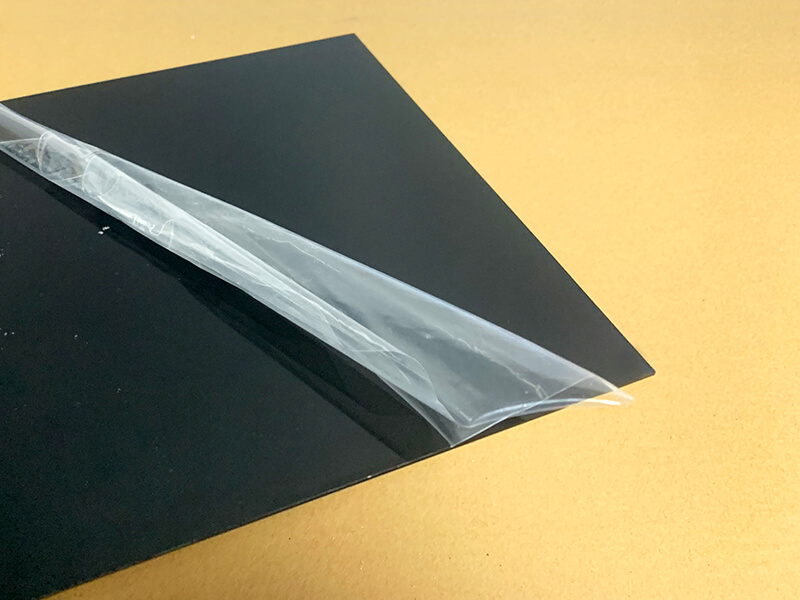

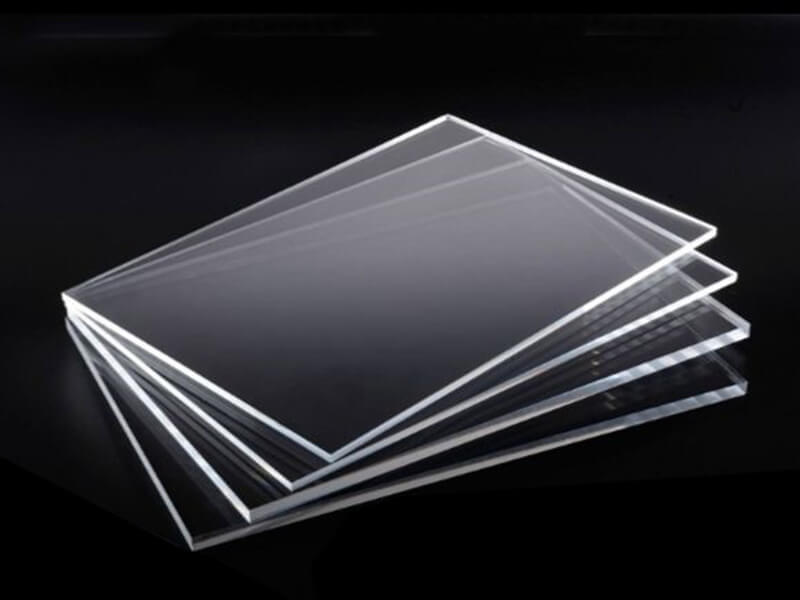

Acrylic

Acrylics can be used for applications where clarity and economics are a high priority. In addition, acrylic channels are appropriate for applications that require high-impact resistance, clarity, durability, and long-term service.

Acrylic channels are supplied in transparent forms and are also available in a variety of colors. In addition, these channels last long and do not deteriorate over time. So, you don’t need frequent replacement once you have got the acrylic plastic channel.

How Are Plastic Channels Manufactured?

An extrusion process manufactures plastic channels.

The extrusion process for the plastic channel starts with collecting raw material in a hover suspended above the conveyance channel. Next, this raw plastic is released from the hopper into the channel.

The long shearing screw of the channel forces the raw materials down the side of the channel. In addition, the friction created by turning the shearing screw generates heat, resulting in the plastic being molten.

Some manufacturers also prefer electronic heating to melt plastic. However, by the time the plastic reaches the end of the channel, it is already melted.

At the end of the channel, a die shapes the melted plastic into useful plastics. In plastic extrusion, the die metal is cut with a hole through which the plastic passes.

When the plastic is allowed through the hole, it gains its shape and comes out with a shape from the die. Afterward, the extruded plastic is allowed to cool and cut and be prepared for the final processing.

Common Uses for Plastic Channels

Construction Industries

Construction companies use plastic channels quite largely. The common uses include- window trim, insulation, outdoor siding, outdoor gutters, indoor and outdoor trim, indoor doors and gutters, door frame trim and insulation, and guard and bumper around sharp edges.

The construction industry prefers acrylic plastic channels over other options because of the durability and clarity of acrylic channels. They do not crack or shatter upon impact and are also available in a wide range of colors.

Appliance Manufacturer

Appliance manufacturers prefer flexible acrylic channels for refrigerator and stove door sealants. They are also used as indoor and outdoor trim and bumpers in many automotive industries.

Commercial Manufacturer

Commercial manufacturers use plastic channels to make curtain rods, drinking straws, picture frames, partition holders, shelving, and guards, among other things. In addition, plastic channels are often coextruded, mixing hard plastic with softer plastic to create soft-sealing channels with a hard texture.

Some other uses of plastic channels in our day-to-day lives include:

Custom Plastic Channels

If you require plastic for complex applications you can have your own acrylic custom profile according to your design. However, some of the common types of extruded profiles are listed below-

How Sustainable Is Acrylic Plastic Channel?

When it comes to sustainability, acrylic plastic channels are more sustainable than other plastic channels. Acrylic manufacturers follow environmentally friendly manufacturing processes, which result in high-quality and durable acrylic profiles produced without causing any significant impact on the environment.

Conclusion

Plastic channels are used everywhere in our daily lives for both indoor and outdoor purposes. Therefore, you need to choose the right material and shape for your purpose before you order it. Other plastic types like PP, PE, or ABS can be fit if you want it for a short-term purpose or a temporary cause. However, for long-term purposes, acrylic can serve you well. Acrylic profiles are flexible or rigid in different forms and colors, so you don’t have to worry about acrylic being inappropriate.

Need A Trustworthy Supplier Of Acrylic Product

Click on the button, you will find the Trustworthy Supplier Of Acrylic-based product and machining services.