Ultimate Guide for Acrylic Vs. Polycarbonate

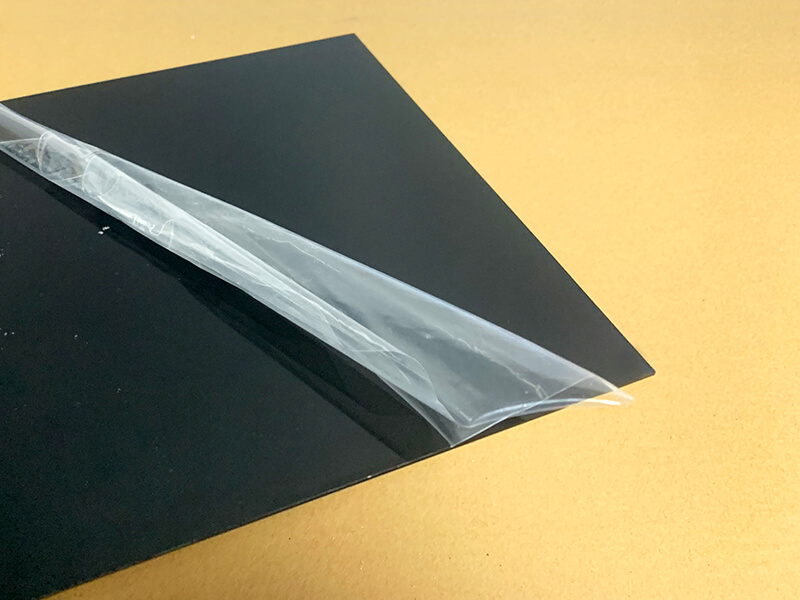

What Is Acrylic?

Acrylic is a sort of plastic that is solid, stiff, and optically clear translucent. It has excellent strength and stiffness. Apart from that, it is simple to fabricate, adheres well to adhesives and solvents, and thermoforms easily. Normally, it can be made to plexiglass sheet, acrylic rod, and acrylic tube.

Acrylic is best known as the most convenient alternative to glass. Its ultra-level of light transmission and transparency with incredible strength makes it a better alternative for glass applications.

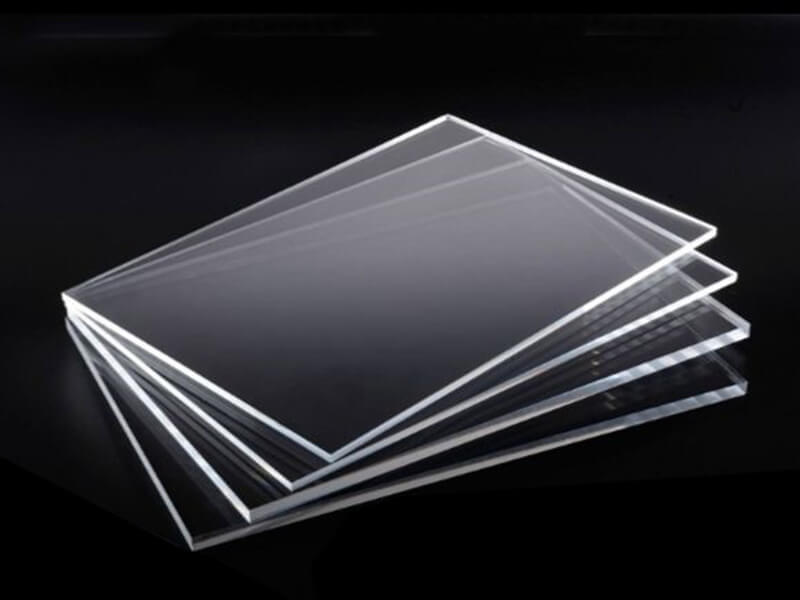

What Is Polycarbonate?

Polycarbonate is also a solid and clear plastic with excellent stiffness like acrylic. Due to its visual clarity, it is widely used in applications like Machine guards, signs, mask shields, skylights, and POP displays. Magnesium, carbon, and calcium are used to prepare polycarbonate sheets.

Acrylic vs Polycarbonate

To differentiate between acrylic and polycarbonate, we need to understand their properties specifically. Although in terms of components and applications, they are often similar.

Let’s find out how we can differentiate them considering their properties.

Durability and Strength

During the production phase, polycarbonate is more durable, whereas acrylic can bend when heated. Contrarily, polycarbonate can be molded in cold temperatures or bent without the use of heat.

Both are strong and provide impact resistance. But as exposed to stress, acrylic cracks more readily than polycarbonate.

Clarity

Acrylic outperforms polycarbonate when it comes to transparency because it allows you in more light with a light transmittance of 92 percent versus 88 percent for polycarbonate.

Both are effective for glazing. However, acrylic can be polished to restore its transparency, whereas polycarbonate cannot.

Scratch Resistance

Acrylic is more scratch-resistant compared to polycarbonate. One of the best parts is-it is more resistant to UV light and does not turn yellow. On the other hand, polycarbonate can turn yellow over time and is more susceptible to scratches.

Chemical Reactions

When you consider the chemical tolerance, polycarbonate wins. But for abrasive cleaners, it is not often resistant. In this case, Acrylic is better at resisting.

Gasoline Resistance

Most of the manufacturers prefer acrylic for this property. It is resistant to gasoline and ensures a lower chance of burning. Polycarbonate is less resistant to gasoline than acrylic.

Aesthetics

One of the useful features of acrylic is its smooth, shiny exterior. When manufacturers prefer the exterior glow on the finish, acrylic provides the best.

Providing more detail in sign design and color scheme, acrylic lighted sign panel may be a big plus. Although, polycarbonate has an appealing exterior glow as well.

Adaptability

Polycarbonate is more flexible than acrylic. Because it can be easily bent without using heat, on the other hand, acrylic needs heat for bending.

Maintenance

You can clean both acrylic and polycarbonate naturally and comfortably. Just need to use a microfiber or a piece of fabric made of cotton. But for acrylic, you need warm soapy water. Whereas for polycarbonate, you have to use cleaners of organic additives that are more abrasive.

Cost

When it comes to affordability, acrylic is normally less expensive than polycarbonate. To be very exact, it is 30% less cheap.

Pros and Cons of Acrylic

Pros

Cons

Pros and Cons of Polycarbonate

Pros

Cons

Which One Is Better For You and Why?

Both acrylic and polycarbonate are popular and clear plastics to use for the manufacturing processes. So the question is which one is better? Well, it depends on your project requirement and preferences.

We recommend both materials; actually, it depends on your situation and project requirement. So try to fix your needs first and then choose accordingly.

What To Consider When Making Your Decision?

Before purchasing a suitable one for your project, you need to compare the properties of both materials. We have made a clear comparison for you.

You can consider these for your project. Furthermore, the application plays a bigger role in deciding whether to use acrylic or polycarbonate. For your consideration, here are some perfect applications for both kinds:

Acrylic Plastic Application

Polycarbonate Plastic Application

Verdict

So you see, in terms of physical and chemical properties, both acrylic and polycarbonate have distinctions. Moreover, their applicability plays a huge role.

Your requirements and preferences are the considerations to be focused on when purchasing. However, both are popular and effective enough to meet all your needs.

UVACRYLIC is a leading manufacturer of acrylic sheets in China, which provides plexiglass sheets in all forms and custom acrylic. The parent company, UVPLASTIC, is a top manufacturer of polycarbonate sheets, and integrated machining services.

Need A Trustworthy Supplier Of Acrylic Product

Click on the button, you will find the Trustworthy Supplier Of Acrylic-based product and machining services.