What is Acrylic Infrared Transmitting Sheet, How Does It Work?

The growth of infrared imaging technology in industries like the military, automotive, healthcare, etc., has increased the demand for Acrylic infrared transmitting sheets. This unique plastic is also used for household purposes.

So, if you are an industry professional and a simple homemaker dealing with the issue of transmitting IR, this unique plastic is for you. We know you must learn details about this plastic and its working process before purchasing.

In this article, we provide a comprehensive guide on this special Acrylic plastic so that you can make an informed decision about using it.

What is an Acrylic Infrared Transmitting Sheet?

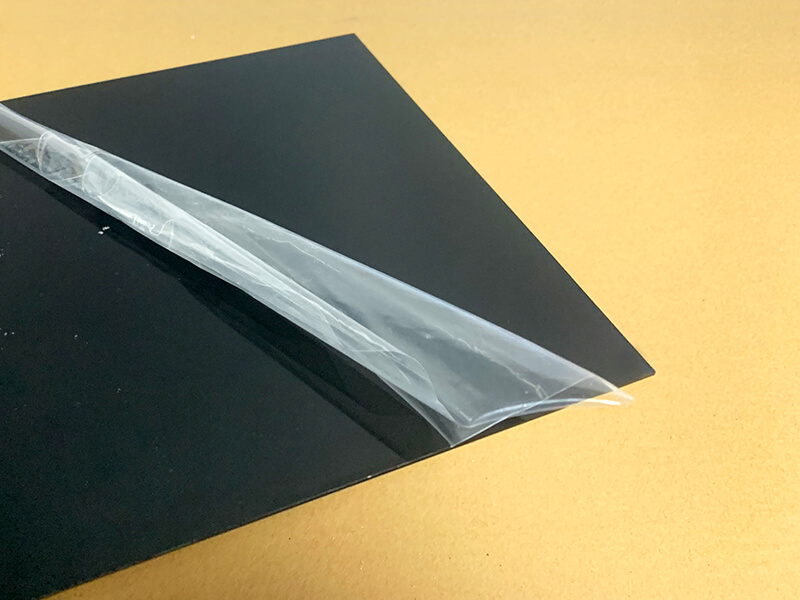

Acrylic infrared transmitting sheet is a specialized construction material known as IR Acrylic to manufacturers and plastic-production industry experts. IR Acrylic can obstruct the passage of conventional or visible lights while allowing infrared lights or radiations to pass through.

In this case, this plastic sheet allows transmission of IR 750 nm or more. Most importantly, Acrylic infrared-transmitting plastic sheets also block UV rays.

Characteristics

The following are the general characteristics of Acrylic infrared transmitting sheets.

Most Common Applications

The following are the most common applications of Acrylic infrared transmitting sheets.

Pros and Cons

The table below is designed to inform you of the advantages and disadvantages of using IR-transmitting acrylic pieces.

| Pros | Cons |

|---|---|

| Acrylic IR transmitting sheets are engineered to maximize the transmission of infrared light. | Less or zero resistance against scratches |

| Higher impact and weather resistance | Thermal sensitive |

| Highly customizable and lightweight | Any manufacturing defect can trigger optical distortion |

| Cost-effective | Risk of deformation |

| Low maintenance | Sensitive to some chemical reactions |

How does the Acrylic Infrared Transmitting Sheet work?

In this section, we inform you of the in-detail working process of IR transmitting Acrylic.

Production Process of Acrylic Infrared Transmitting Sheet

It is the same production process for acrylic sheets, with some expectations for coating and the addition of specialized pigments. In the process, methyl methacrylate (MMA) is first produced and converted to PMMA through polymerization.

The soft-form PMMA is cast in the sheets. Finally, the cooling, solidification, and finishing take place. Some manufacturers insert pigments in the 800 to 2500 nanometer wavelength range while PMMA is produced. It is to incorporate a higher degree of IR transmission and block visible light.

On the contrary, most manufacturers coat the sheets with infrared transparent materials in the 800 to 2500 nanometer range. The coating materials vary depending on the formula used, manufacturer’s preferences, etc.

The most common materials are Zinc Sulfide, Germanium, Silicon, Magnesium Fluoride, etc. Again, the coating can be made of indium tin oxide, titanium dioxide, nickel oxide, etc. You must know that a 380 to 750-nanometer coating can effectively block visible light’s passing.

Mechanism of IR Transmitting Acrylic Sheet

As we have already produced the IR transmitting acrylic sheet, it is time to learn its mechanism.

First, the sheet’s respective coating and specialized pigments block the passage of visible light as its wavelength is 380 to 750. Here, the protective element’s capacity to block wavelength ranges from 800 to 2500 nanometers.

Second, per the basics, the UV ray’s wavelength is 100-400 nm. So, the respective Acrylic cover also blocks the passage of UV rays.

Third, the Acrylic sheet allows the transmission of infrared rays with 800 to 2500 or higher nanometer wavelengths. You should know this wavelength is defined as the wavelength of near-infrared rays. Meanwhile, the wavelength can reach 50,000 nm for infrared rays.

In short, this Acrylic plate absorbs or reflects the visible light, and the IR passes through it.

Working Curve of IRT PMMA

Infrared Transmitting PMMA

End Talks

We expect that you will now have an in-depth understanding of every aspect of acrylic infrared transmitting sheets. You can now choose this specialized Acrylic cover or another plastic cover based on your requirements.

Finally, we want to inform you of the cost of this sheet. On average, $40 is about one square meter IR transmitting Acrylic sheet. The price excludes cutting or any customization work costs. However, the price can vary based on the manufacturer and the purchasing quantity.

Need A Trustworthy Supplier Of Acrylic Product

Click on the button, you will find the Trustworthy Supplier Of Acrylic-based product and machining services.