Different Types of Acrylic Infrared Transmitting Sheets

Find out all about acrylic infrared transmitting sheets! Learn which types are used in different infrared technologies and choose the right one for you.

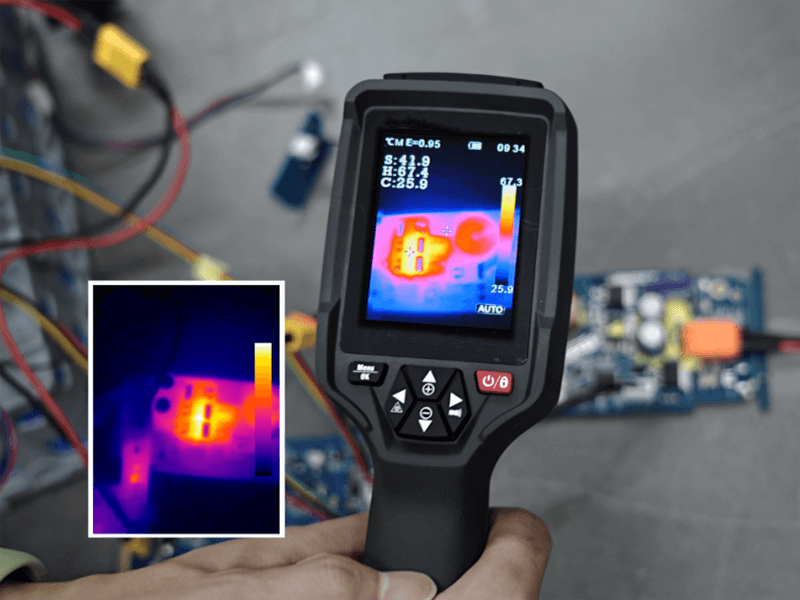

Have you ever wondered about a single new plastic that is now used in almost every infrared technology? Infrared-transmitting acrylic sheet allows infrared light to pass through and blocks visible light. This valuable feature makes it ideal for industries ranging from medical equipment and security systems to remote controls and optical applications.

Now point to note that different ranges of acrylic sheets are now used in different sectors. If you’re new to using acrylic, you must understand these types to choose the right one for your project. This guide will help you learn about the different acrylic infrared transmitting sheets and their best uses.

What is an Acrylic Infrared Transmitting Sheet?

Infrared-transmitting plastic is a high-grade plastic that is designed to absorb harmful UV rays and other visible light while allowing infrared light. The sheet is essential for those special projects that require a fluent IR transmission starting at 750 nm.

They offer high clarity, durability, and sometimes additional features like heat or chemical resistance. Due to all these unique values in a single place, the sheet is now highly used in various applications in our daily lives.

What Are the Different Grades of Acrylic Infrared Transmitting Sheets?

Let’s start with highlighting different grade acrylic sheets you will find used for different industrial purposes. Have a quick glimpse at some of the most common ones:

1. Standard Acrylic Sheets

This is more likely known as the general-purpose acrylic infrared transmitting sheet. Due to their unique higher molecular structure, these types of acrylic sheets are ideal for most standard applications where high performance isn’t critical.

It’s easier to fabricate, machine, and laser-cut compared to extruded acrylic. More than that, 3mm clear cast acrylic allows about 90% of infrared radiation to pass through in the 700 to 1400 nanometer wavelength range.

2. Medical Grade

As the name suggests, infrared-transmitting acrylic sheets in the grade are used in various medical and healthcare applications, mainly to ensure safety and reliability. Its first significant use was in incubators, which have been safely used in contact with human tissue since the 1950s.

As time goes on, the usage of these versatile in medical grade is increasing day by day. In the case of infrared-transmitting acrylic, you will find it in the medical field for making various devices and components where IR transmission and UV blockage are crucial.

3. High Transmission Grade

This is another mostly used infrared-transmitting acrylic that is opaque to visible light and effectively allows the highest amount of infrared light to pass through.

Even the unique properties of high-transmission acrylic absorb UV rays, making it efficient for use in devices where UV blockage is a must.

Different Types of Acrylic Sheets That Can Transmit Infrared Light?

You will find different types of acrylic sheets in various applications. Each of them has unique physical properties that make it ideal to use for that specific need. Here are some of the most common infrared-transmitting acrylic sheets you can note down:

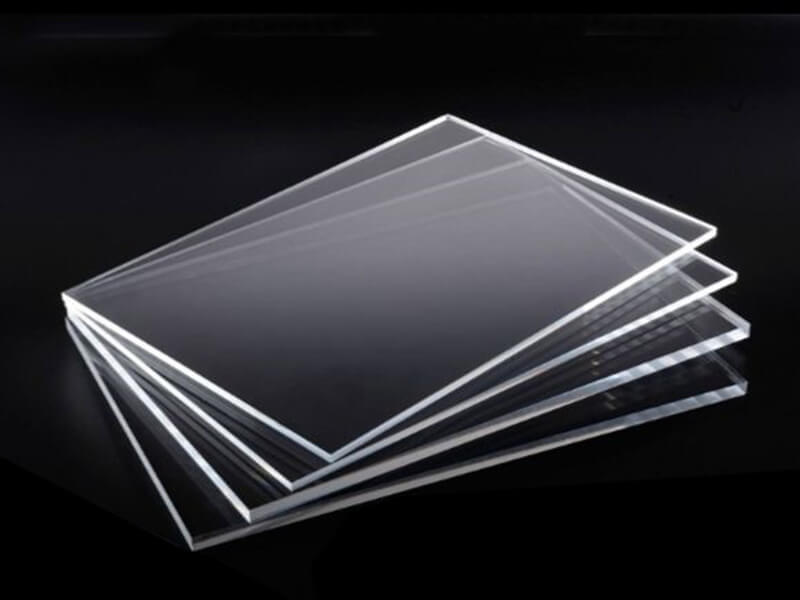

1. ACRYLITE® Cast (GP)

It is a high-quality cast acrylic sheet widely used due to its optical characteristics, thickness tolerances, light stability, and low internal stress levels.

This range of acrylic sheets is manufactured to precise standards to ensure optimal IR performance on the devices. It offers a high-performance infrared transparency where you will get 90% IR radiation to pass through at a thickness of 3 mm.

Key Features:

Applications

This sheet is widely used in applications where the manufacturer must ensure high transparency and durability. Common applications include:

2. ACRYLITE® Extruded (FF):

This specialized acrylic sheet is produced through an exclusive extrusion process. This process ensures a clear acrylic sheet with good infrared transmission. The IR transmission capabilities of these acrylics are almost similar to cast acrylic but are more affordable and easier to work with.

Key features:

Application

Due to its virtually distortion-free clarity, you will find it used in various applications, including:

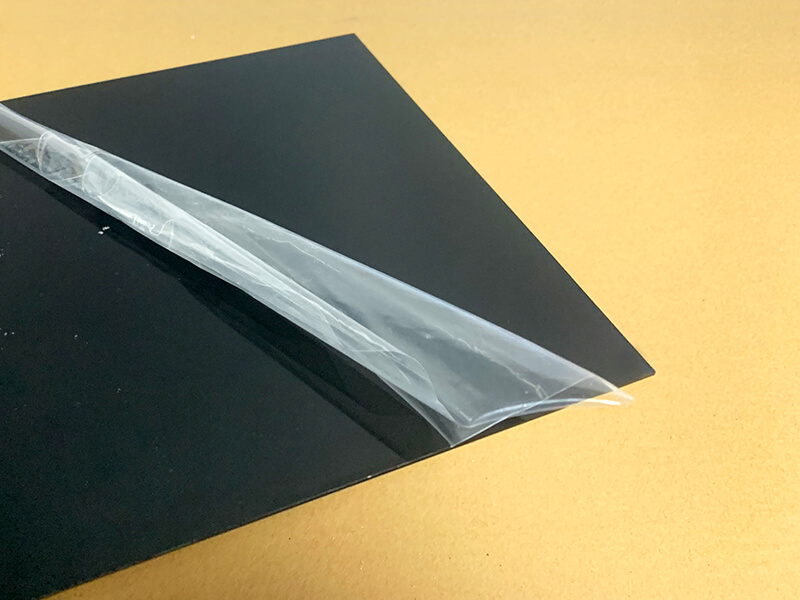

3. ACRYLITE® IR Acrylic 1146

This type of acrylic is designed specifically for infrared applications. The sheet has the strong physical property to absorb the visible light while allowing the IR light to pass through the application. Typically it comes in black in color, which makes it ideal for use in specialized uses.

Key Features & Applications

4. Plexiglas® IR Acrylic 3143

This type of infrared-transmitting acrylic sheet is designed to meet specific needs where visible light interference needs to be minimized. Also, the specialized physical properties of the sheet can effectively allow the IR signals to pass through from the applications.

Key features

Applications

Plexiglas® IR Acrylic 3143 is commonly found in various applications like remote control devices, laser lenses, and heat sensors. The sheet ensures optimal performance in applications where an effective IR transmission is necessary!

Essential Cleanness & Maintenance Tips for Infrared-Transmitting Acrylic

To ensure the maximum life out of your infrared-transmitting plastic, here are some essential cleaning and maintenance tips you can follow:

In Closing

Different types of infrared-transmitting acrylic sheets are essential in today’s technology, which offers an outstanding ability to let infrared light through while blocking visible light.

Their unique properties make them versatile and valuable, from medical devices and security systems to remote controls. All you need to do is ensure the right types of acrylic IR transmitting sheets for your industrial needs.

Need A Trustworthy Supplier Of Acrylic Product

Click on the button, you will find the Trustworthy Supplier Of Acrylic-based product and machining services.