Acrylic Machining: The Ultimate Guide for Beginners

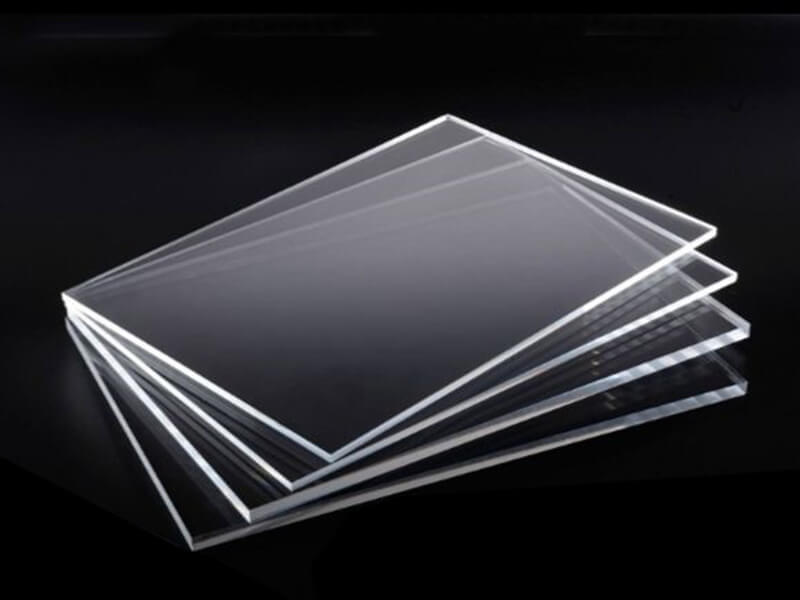

Plastic, in its various forms, has proven to aid people in many ways in the rising manufacturing industry. Acrylic, also called plexiglass or PMMA, is one particular structure. It is a lucid thermoplastic frequently substituted for glass. It is durable, portable, cost-effective, and way less brittle than glass.

Acrylic is helpful for many applications, such as banners for advertising, lights, badges, boxes, etc. Hence, it is vital to continue machining and transforming it. In this article, we will discuss the basics and tips of acrylic machining. We will also talk about polycarbonate and tell you why acrylic is your go-to plastic compared to others. So carry on!

What is Acrylic Machining?

Firstly, you need to know what is acrylic. Acrylic often goes by other names like Plexiglas, Lucite, and the acronym PMMA. PMMA abbreviates Polymethyl methacrylate, its core component chemicals. Polycarbonate and acrylic have some similarities. Click HERE to learn the difference between polycarbonate and acrylic.

Acrylic is cheaper than polycarbonate for machining. The only downside is that it is not as strong as polycarbonate.

Are you wondering if acrylic is machinable? Yes, acrylic is very much machinable. Acrylic machining is a manufacturing procedure that involves cutting and shaping a large workpiece to a desirable shape and size by extracting materials from it.

Additionally, acrylic is much easier to machine than its adversary, Polycarbonate. During acrylic machining, welding, and curving hotlines will also be much more manageable when done with acrylic than with polycarbonate. Moreover, acrylic can still abide with 25 times more resistivity despite being way lighter than glass.

Benefits and Advantages of Acrylic Machining

Acrylic machining is quite lucrative for its rigidity and clarity, and when we say lucid, we mean 92% translucent. Only the small remaining percentage of light is unable to permeate through.

There are many other benefits that we tend to overlook. One of the perquisites of machined acrylic may be that it can take much tension and be stretched flexibly.

Acrylic also has a fantastic bonus. It resists UV rays, making it an ideal substitute for Polycarbonate. Polycarbonate becomes yellow under direct and extended exposure to the sun, and other plastics become delicate, too, so acrylic is the most appropriate material for this aspect.

Plastic is also recyclable if you are thinking of the ecological benefits. Furthermore, it can be turned into different dimensions if you are looking for easy sizing.

Acrylic, furthermore, provides pretty good insulation and can be merged with solvents to create variations for a more contextual effect. It is anti-abrasion and relatively weightless, too, so acrylic can seal the deal for aesthetic purposes as well.

Compared to glass, it is way safer as it retains resistivity against shocks and snaps. Acrylic sustenance in water and corrosion is also laudable in comparison with other plastic varieties.

Milling Vs Turning Method

Milling

Milling is the procedure where rotary clippers are utilized to eject materials or chips by cutting them into a workpiece. We can use various axes or tools for this with varying pressure and techniques. Milling is so diverse that it can have a wide range of methods. They can also have a vast scale of machinations.

If you need to cut any acrylic sheet, milling is a better option than using a saw. A simple saw cannot provide complicated and premium edging.

Milling allows you to make as many and as distinctive shapes as you like. You would most often see milling procedures being done on advertising boards and acrylic signatures.

Turning

Turning is another way of cutting and machining acrylic rods, acrylic tubes, and PMMA film. The tools for cutting into the medium for this process usually consist of no apparent rotary bit.

For this process, the device is moved linearly on a helix route. It’s said to be quite tricky, especially for acrylic since it can be very pliable.

When turning in the inner surfaces, it’s called boring. And when turning is coupled with boring, we can classify them into a broader term known as “lathing”.

Otherwise, you should know more machining methods as follows:

Acrylic Vs Polycarbonate Machining

Polycarbonate sheets and acrylic are both very able plastics with their perks and drawbacks. Without being aware of the characteristics that distinguish them from the others, you will never choose the materials with sound judgment.

Nonetheless, it can be guaranteed that both do very well when utilized in the right field. Below, we will discuss their pros and cons, so read carefully:

Acrylic Machining

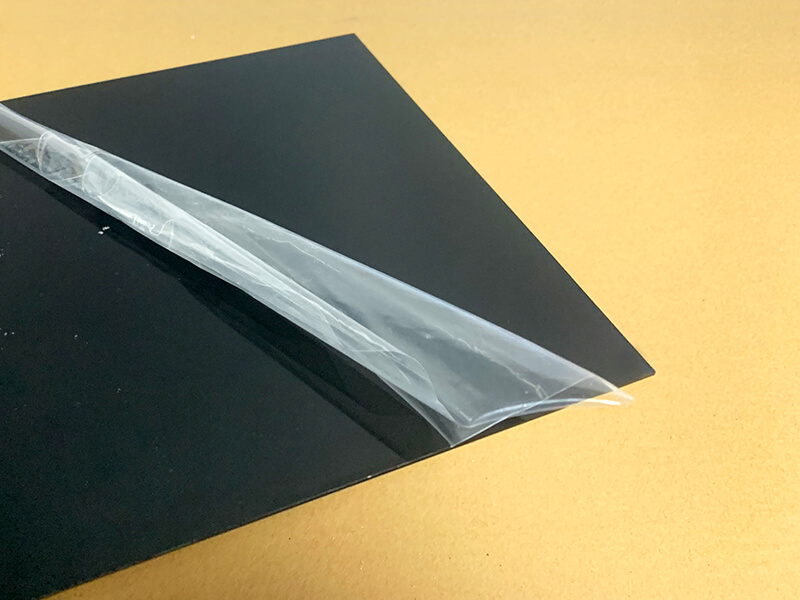

Acrylic, usually transparent, is thermoplastic plastic. We know it by plexiglass as well. You can dye the material in different hues. Variegated opacities can also help with providing distinction.

Pros:

Cons:

Polycarbonate machining

Polycarbonate is also a genuinely translucent thermoplastic. It is found in numerous formations, with the FDA compliant being one of them. It is filled with glass, has improvised bearings, and is made of a quality grade.

Pros:

Cons:

Tips to Ensure Highest Quality

Need A Trustworthy Supplier Of Acrylic Product

Click on the button, you will find the Trustworthy Supplier Of Acrylic-based product and machining services.